AEROSPACE QUALITY

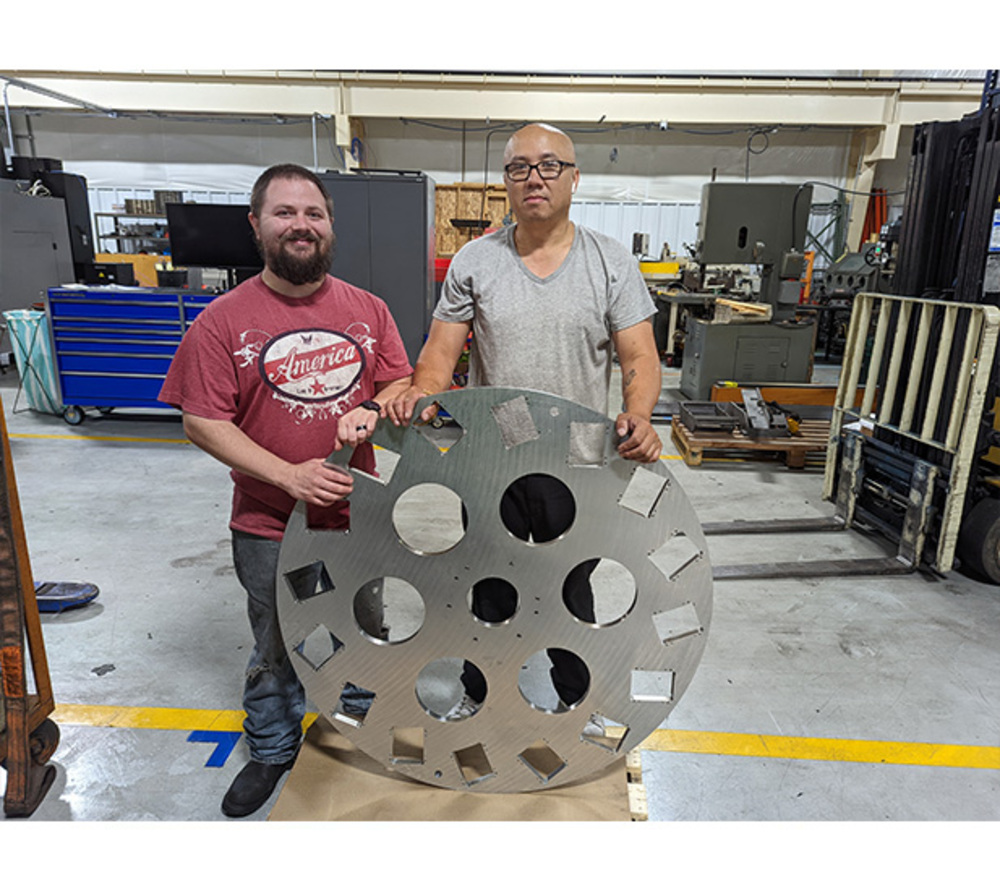

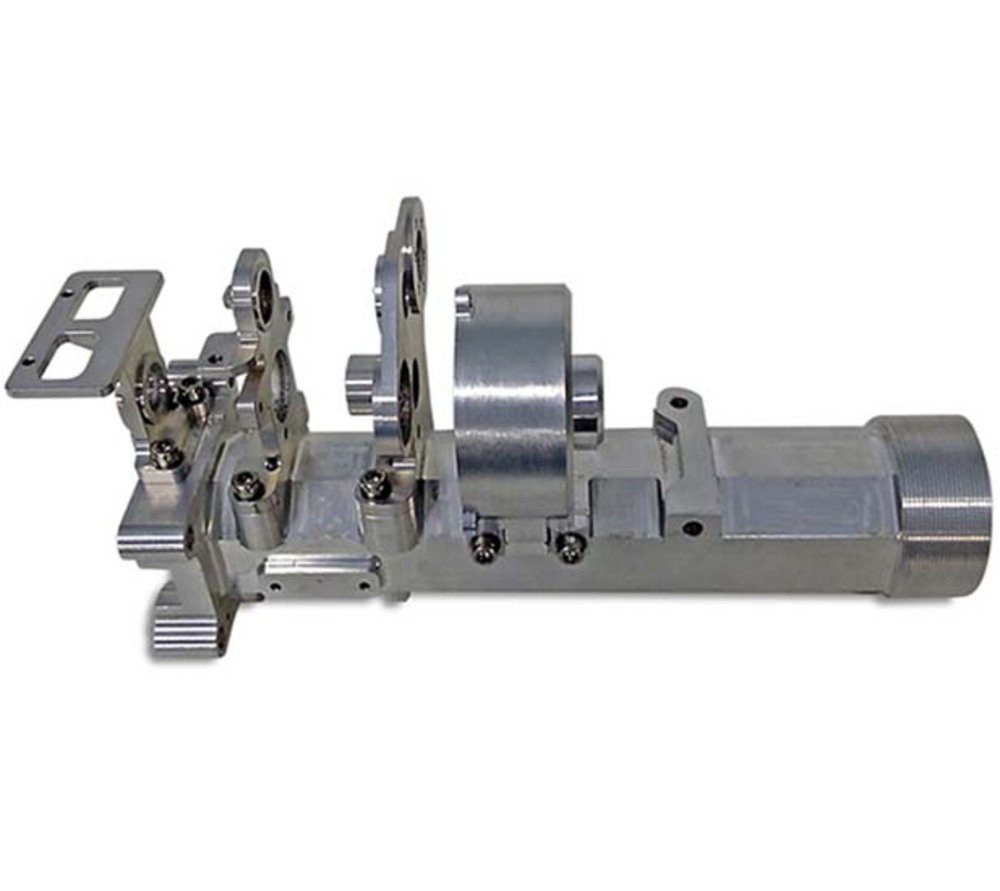

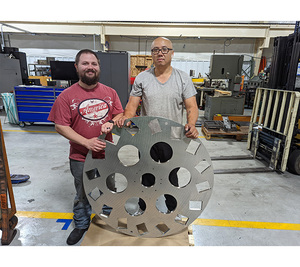

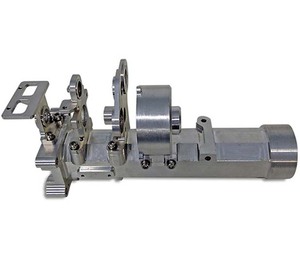

AMD&E is a trusted manufacturer of mission critical parts, subassemblies, systems, and often-entire products. We specialize in aerospace quality mid-size; mid volume parts and assemblies delivered on an accelerated timeframe. Our clients receive the highest quality American made machined parts allowing them to compete successfully on a global scale.

ACCELERATED DELIVERY

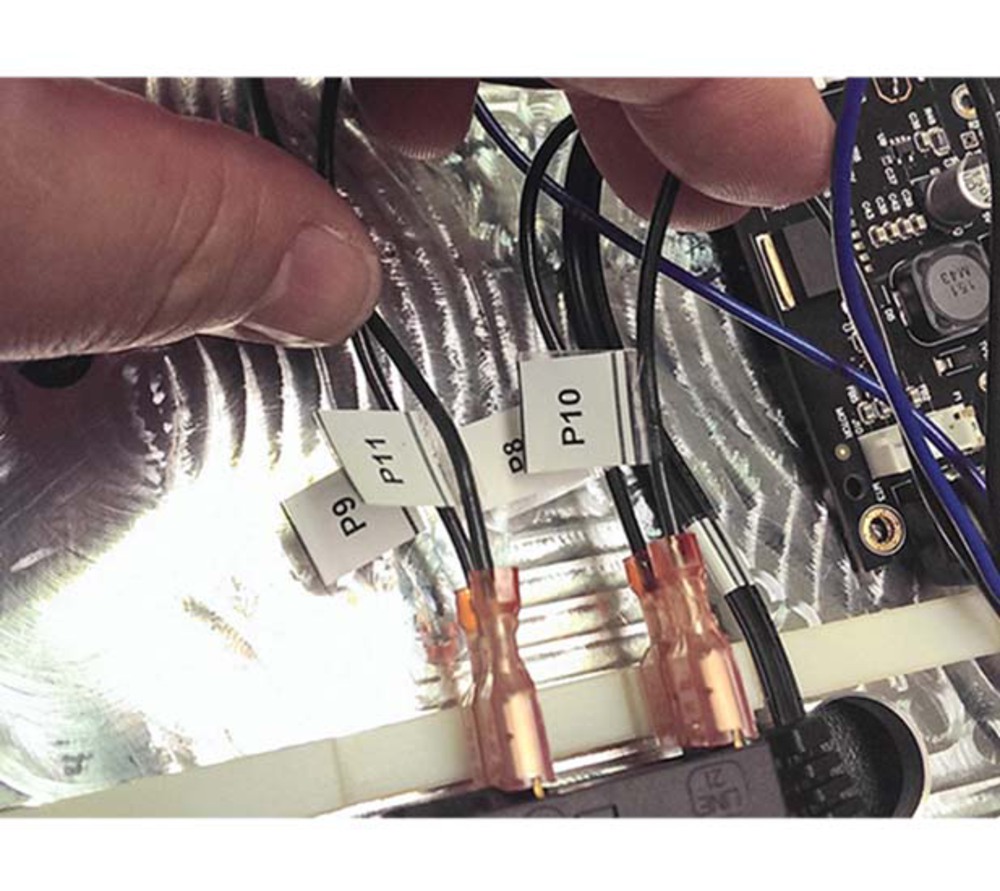

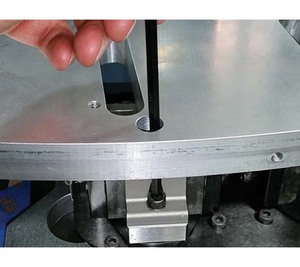

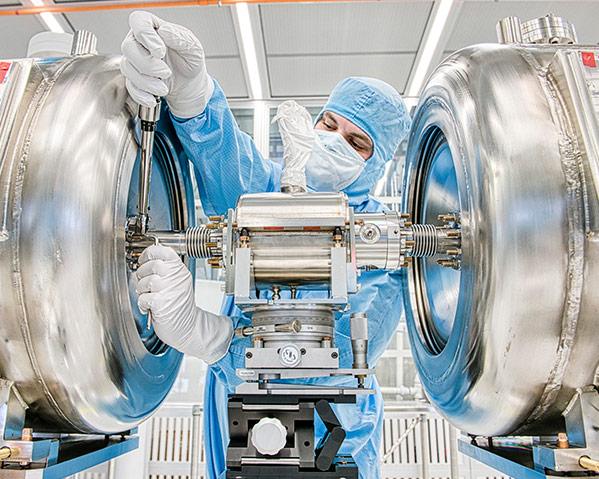

Customers count on us to manufacture specification driven components and systems used in precision motion control, positioning, lightweight structures, power transmission, material handling, fixturing and locating. They also rely on us for rigorous program management, quality control, inspection and precision testing capabilities and repeatability down to the micron level.

GLOBALLY COMPETITIVE

We specialize in precision NC machining and turning of aluminum alloys, stainless steels, titanium, brass, plastics, and other engineering materials, serving a variety of industries where quality and precision are the highest priority.

LOCALLY MANUFACTURED

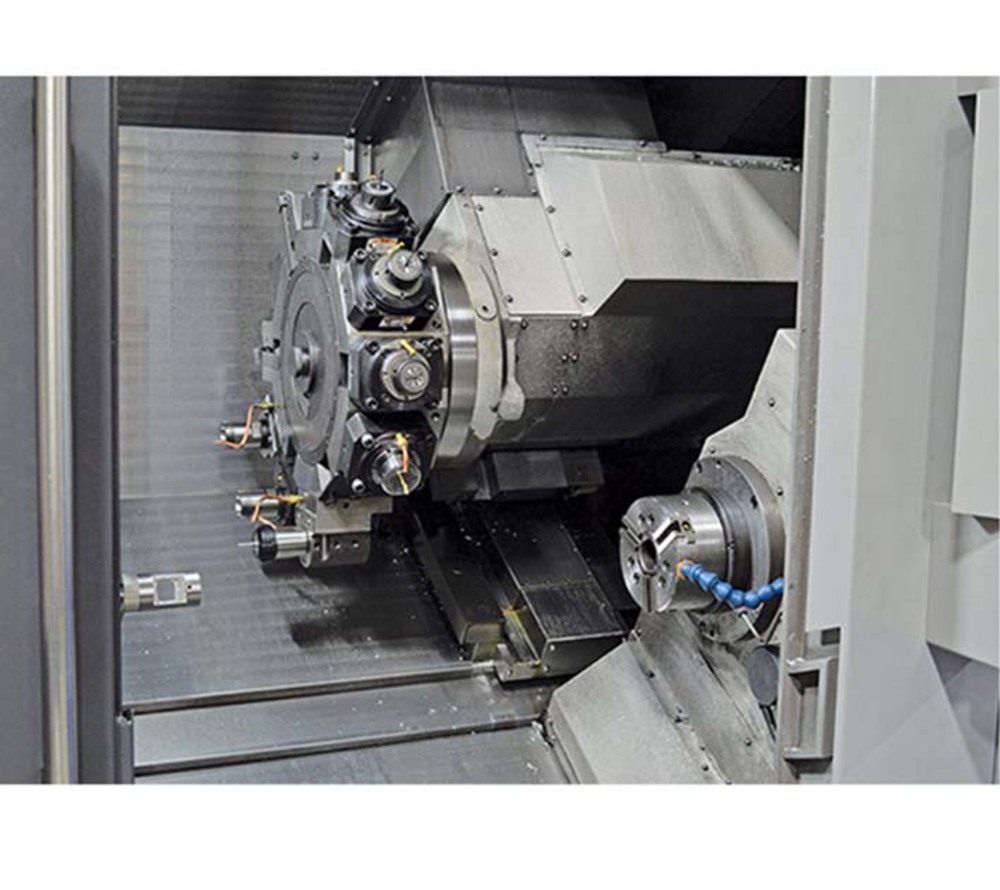

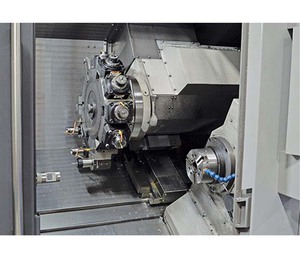

We employ state-of-the-art manufacturing technology, with an average asset age of just three years, ensuring our customers the best possible outcomes.

MANUFACTURING SHOWCASE

MANUFACTURING CAPABILITIES

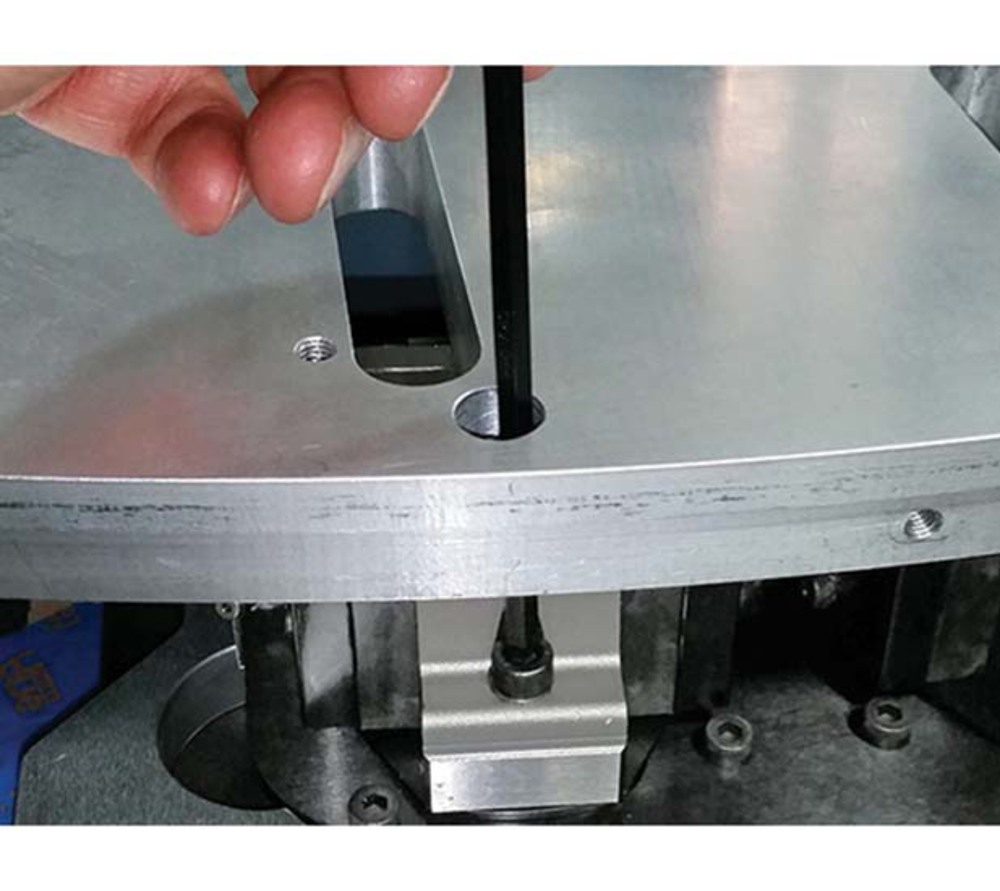

CNC Machining

- Prismatic Machining from 0.5" Cube to 120" X 60" Cube

- 3, 4, 5 Axis Machining

- 5 Face Bridge Milling

- Machining of Castings, Forgings, Stampings

- Weldments and Fabrications up to 120" X 63" X 48"

- Match Machined Housings, Thin-Walled Aero & Space Structures, Light Weight Structures, High Temperature Alloys, Motion Control Components, Optical Components

- Weldments, Bases, Frames, Ground Plates, Plattens, Mold Bases, Gun Drilled Housings, Gun Drilled Tombstones, Hog Outs

- Aluminum alloys, stainless steel alloys, titanium alloys, Steel & tool steel, brass, plastics, and other engineering materials

- Tight Tolerance & Precision Parts

CNC Turning

- Turned part sizes from 1" diameter to 25" diameter

- Turn-Mill up to Ø8" (Lower Volumes Ø12")

- Chucker Parts & Done-in-one

- Sheaves, Couplings, Adapters, Flanges, Housings

- Aluminum alloys, stainless steel alloys, titanium alloys, Steel & tool steel, brass, plastics, and other engineering materials

Grinding

- Surface Grinding – Up to 24" Long X 12" Wide Parts

- Rotary Surface Grinding – Up to Ø16" X 2" Thick parts

- Steel alloys

Laser Marking

- Serial Numbers

- Labels

- Images

- 2D and 3D

- Marking of steel alloys, aluminum alloys, and most plastics

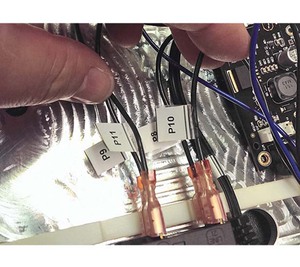

Inspection

- Manual CMM for quick verification

- Portable Micro CMM for quick verification & high accuracy

- Portable Large format CMM – up to 30' work zone

- Surface Gauges

- Manual Inspection - Micrometers, calipers, surface gauges, height gauges

- Surface Finish

- Hardness

Secondary Operations – Local Supply Chain

- Anodize, Black Oxide, Passivate, Chem Conversion Coat

- Blast

- Paint

- Powder Coat

- MPI, NDT

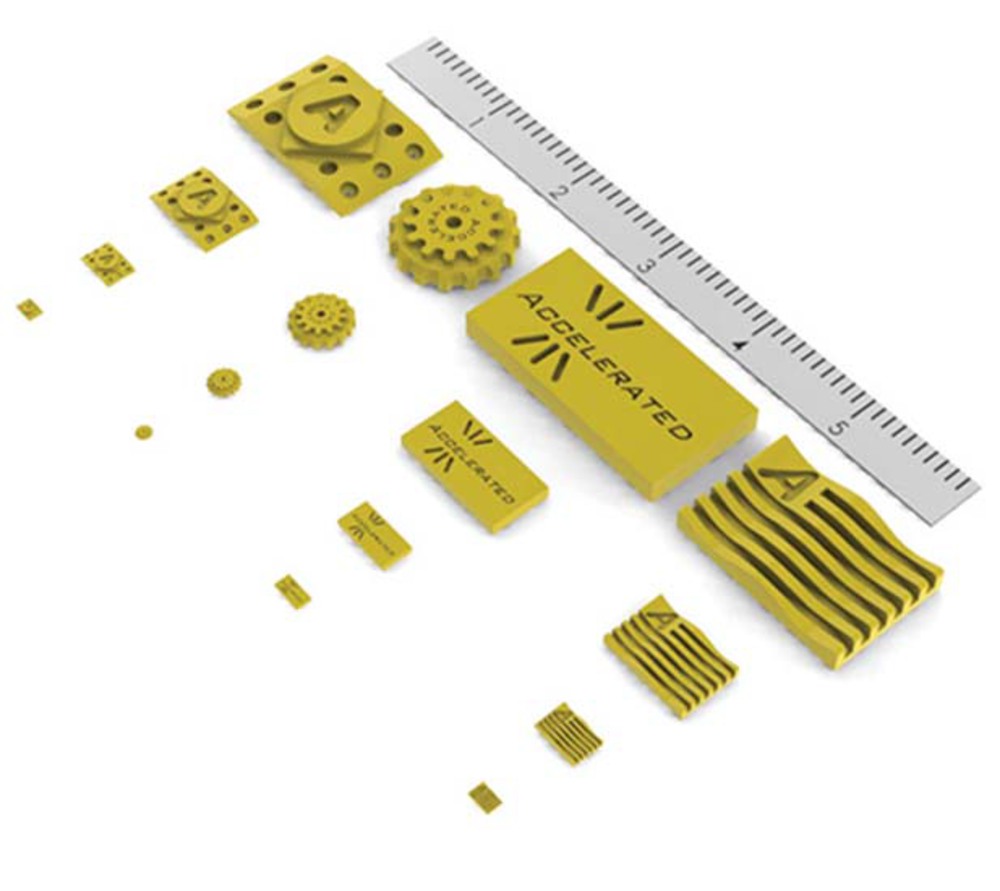

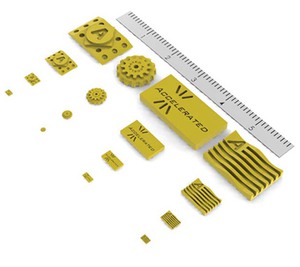

Plastics

- 3D Printing

MANUFACTURING ASSETS

Markets We Serve

Space, Aerospace, Defense, Military

Energy

Clean Water, Food & Beverage

Biotech, Life Sciences, Agri Science

Healthcare Equipment

Agriculture, Off-Highway & Automotive Machinery

General Manufacturing & Industry

Precision Machinery Industry