Rebuild and Repair Services

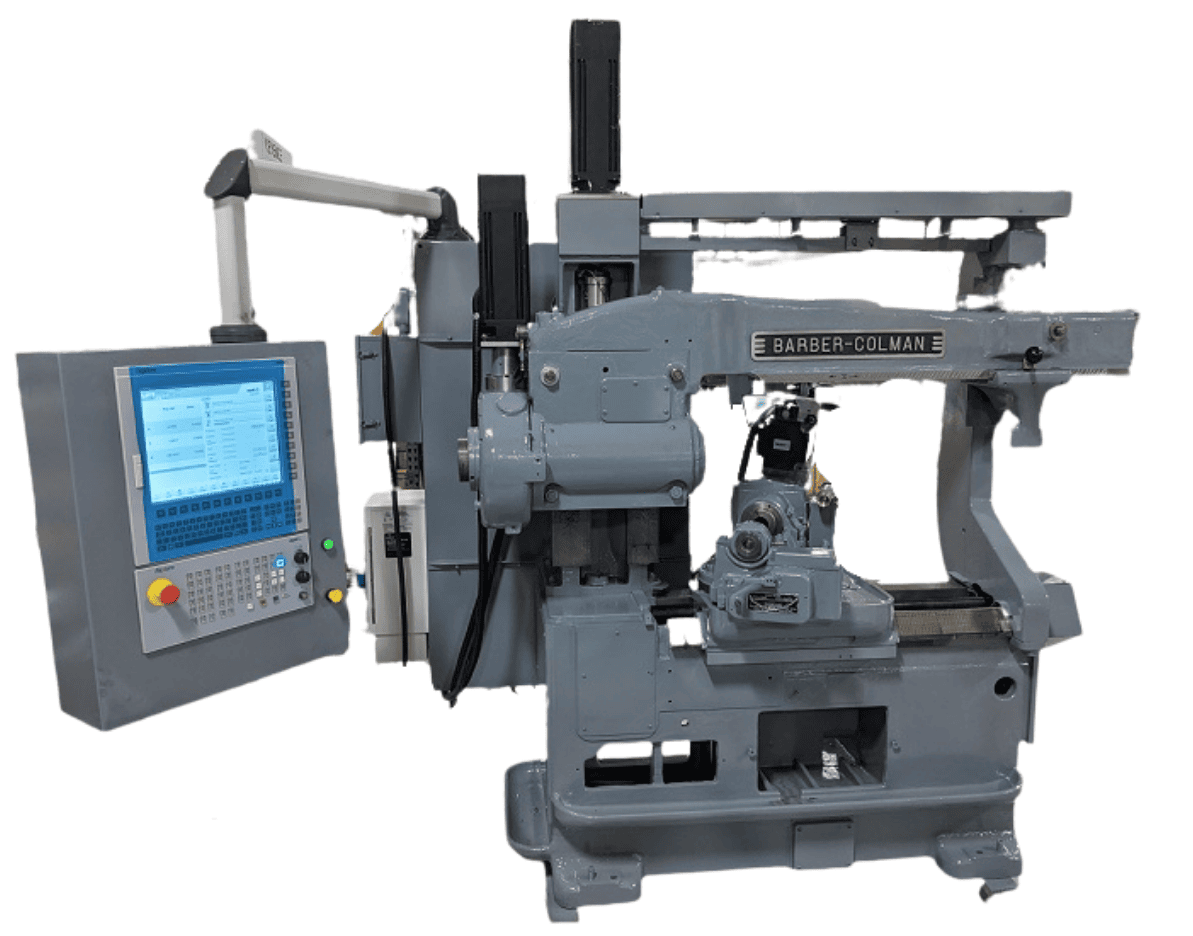

Transforming vintage iron into state-of-the-art machines with better than new condition

Because companies need to revitalize useful manufacturing equipment with new technology that does not break the bank.

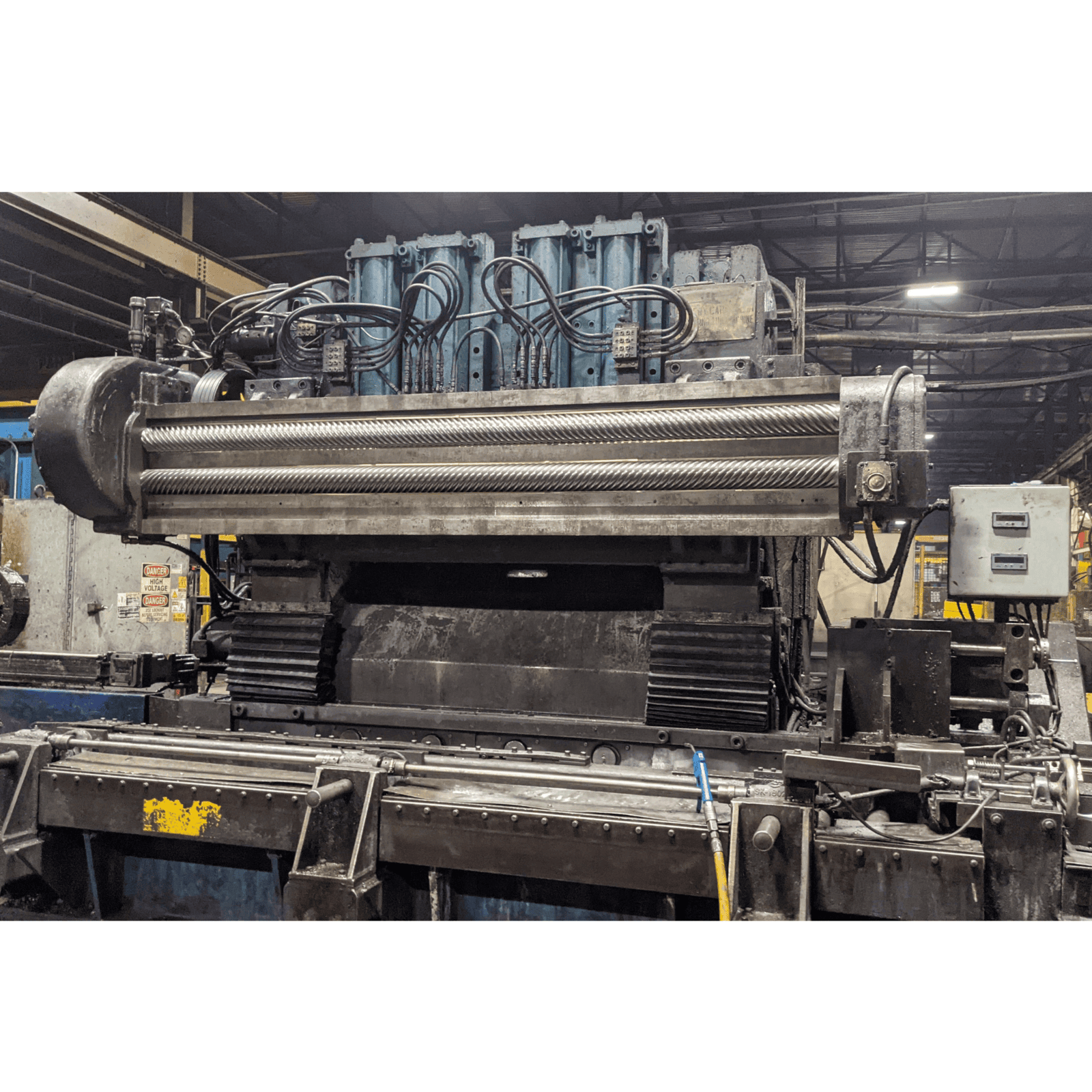

Your manufacturing equipment has been in operation for years—sometimes even decades—but has now deteriorated and no longer operates as efficiently as it did in the past. You can decide to replace it, repair it, or you can choose to have us rebuild it to better than new condition.

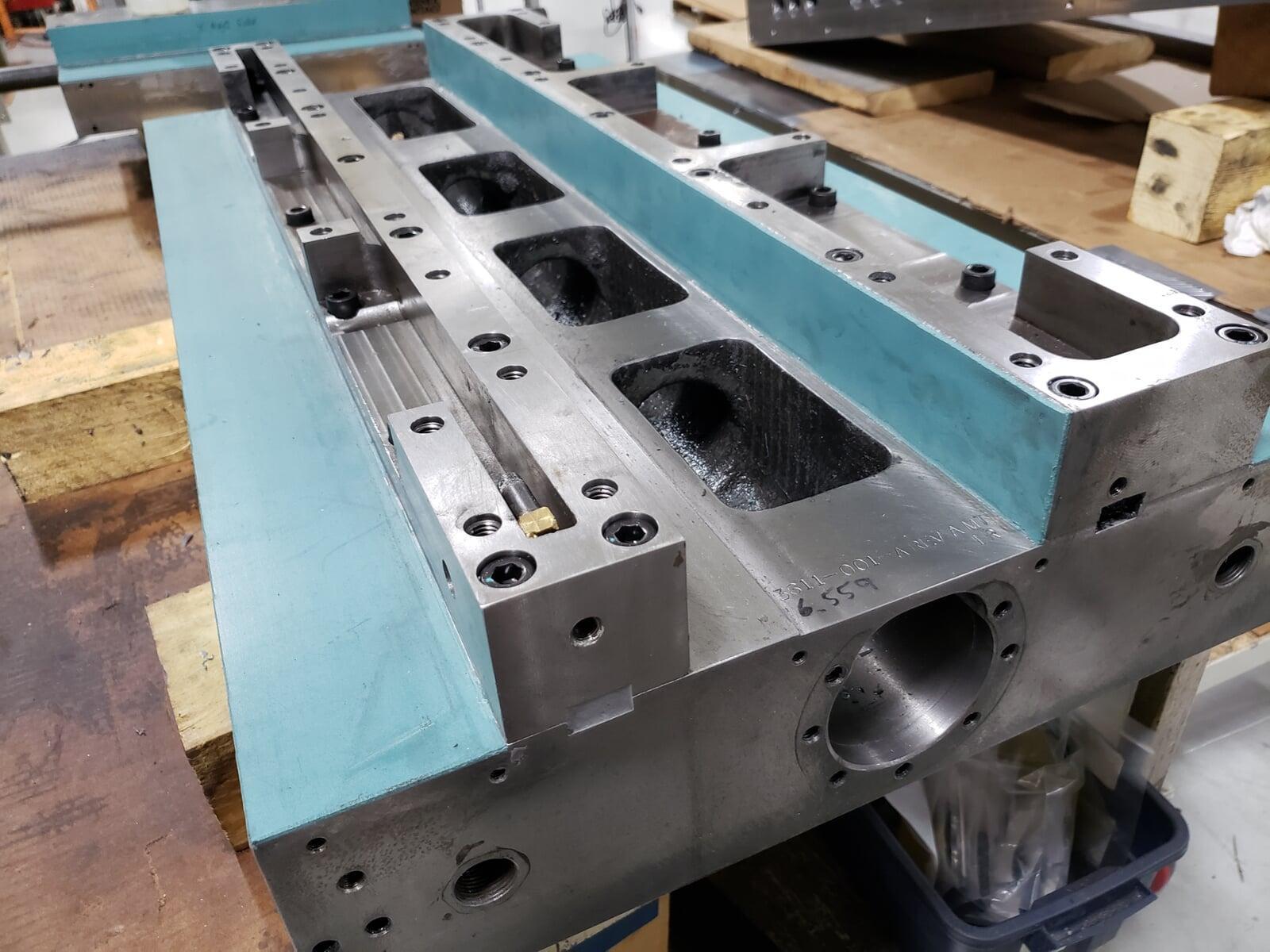

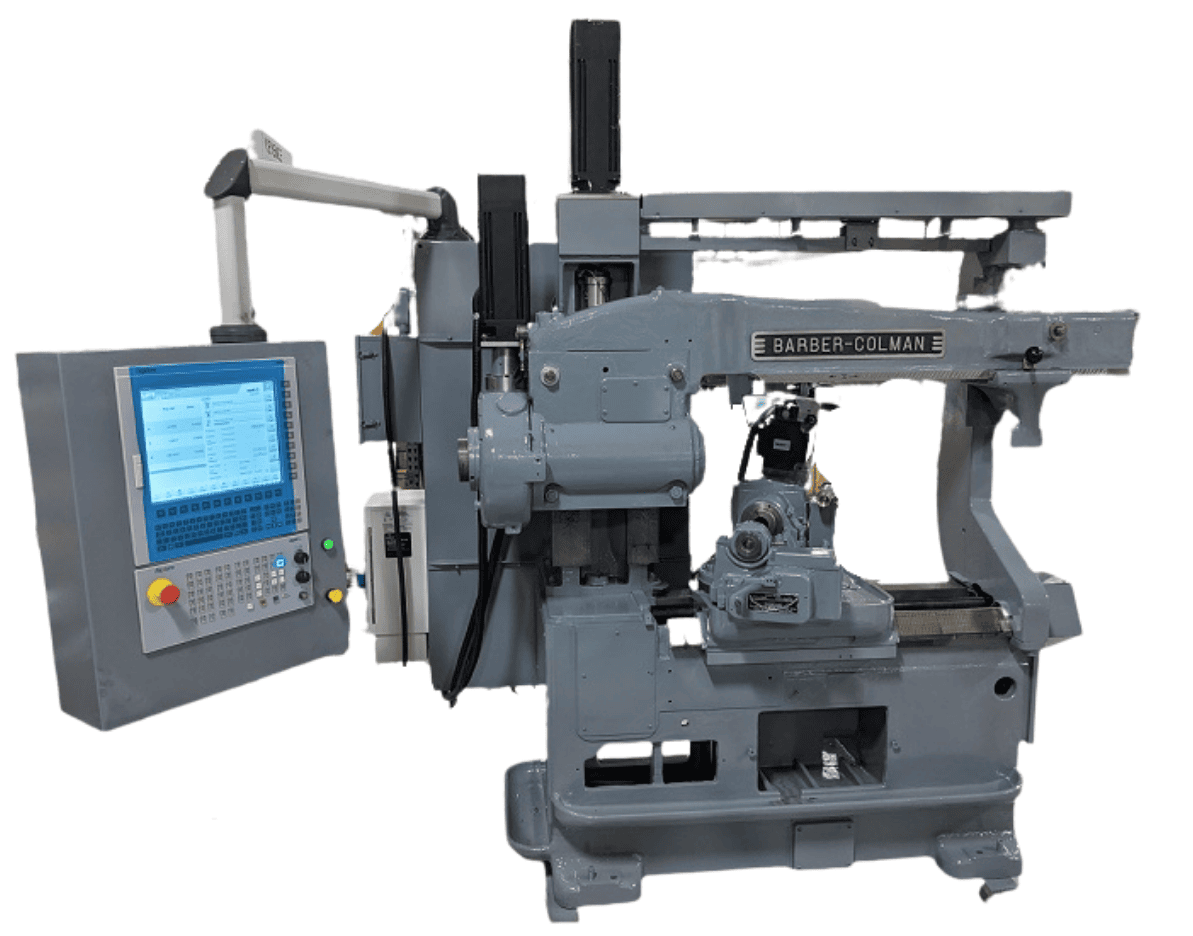

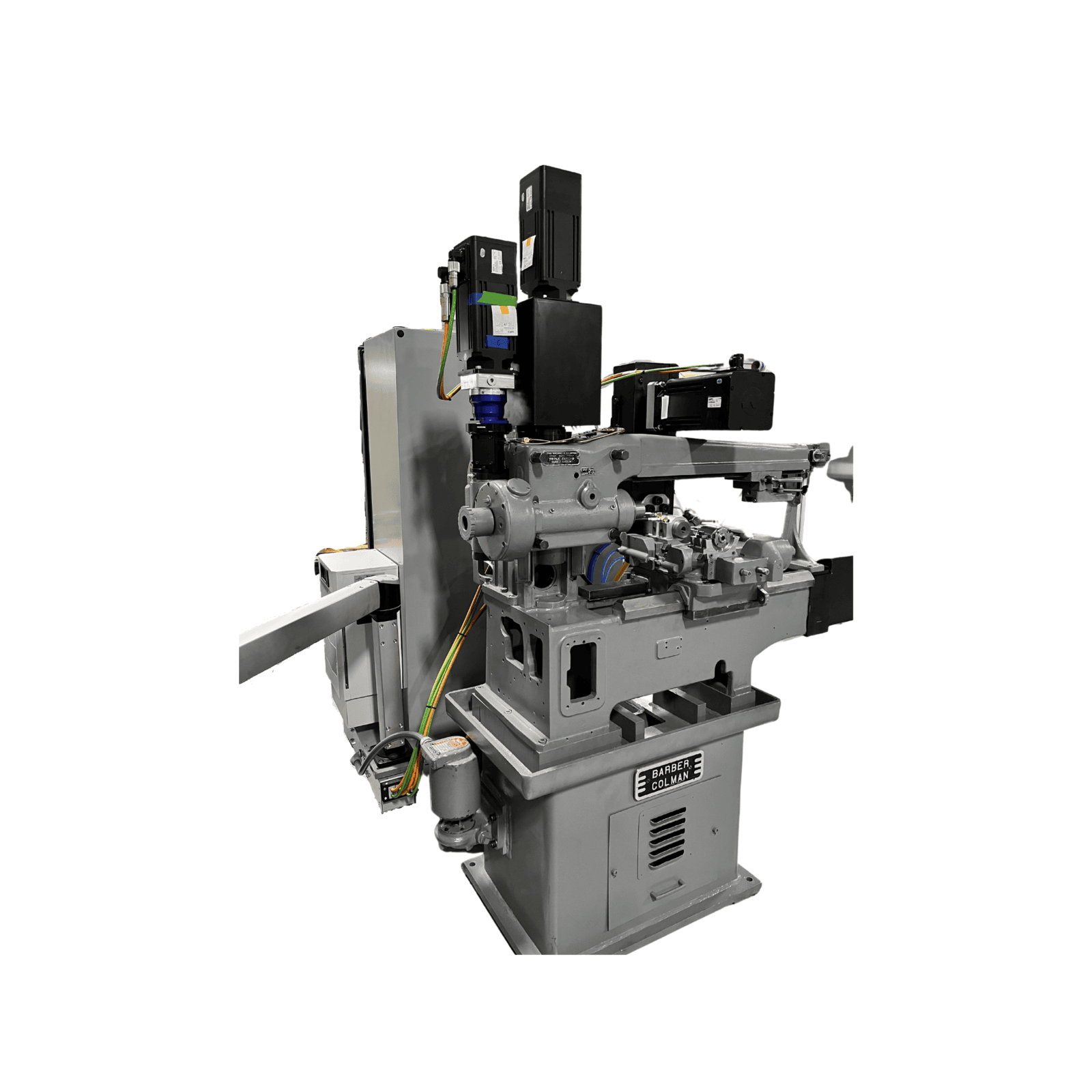

Our team can upgrade metal cutting machines with new CNC Controls, servo motors, and controls as well as upgrade guiding elements to establish better than new precision. Coupled with our engineering capabilities, we can reverse engineer worn out parts that can no longer be sourced.

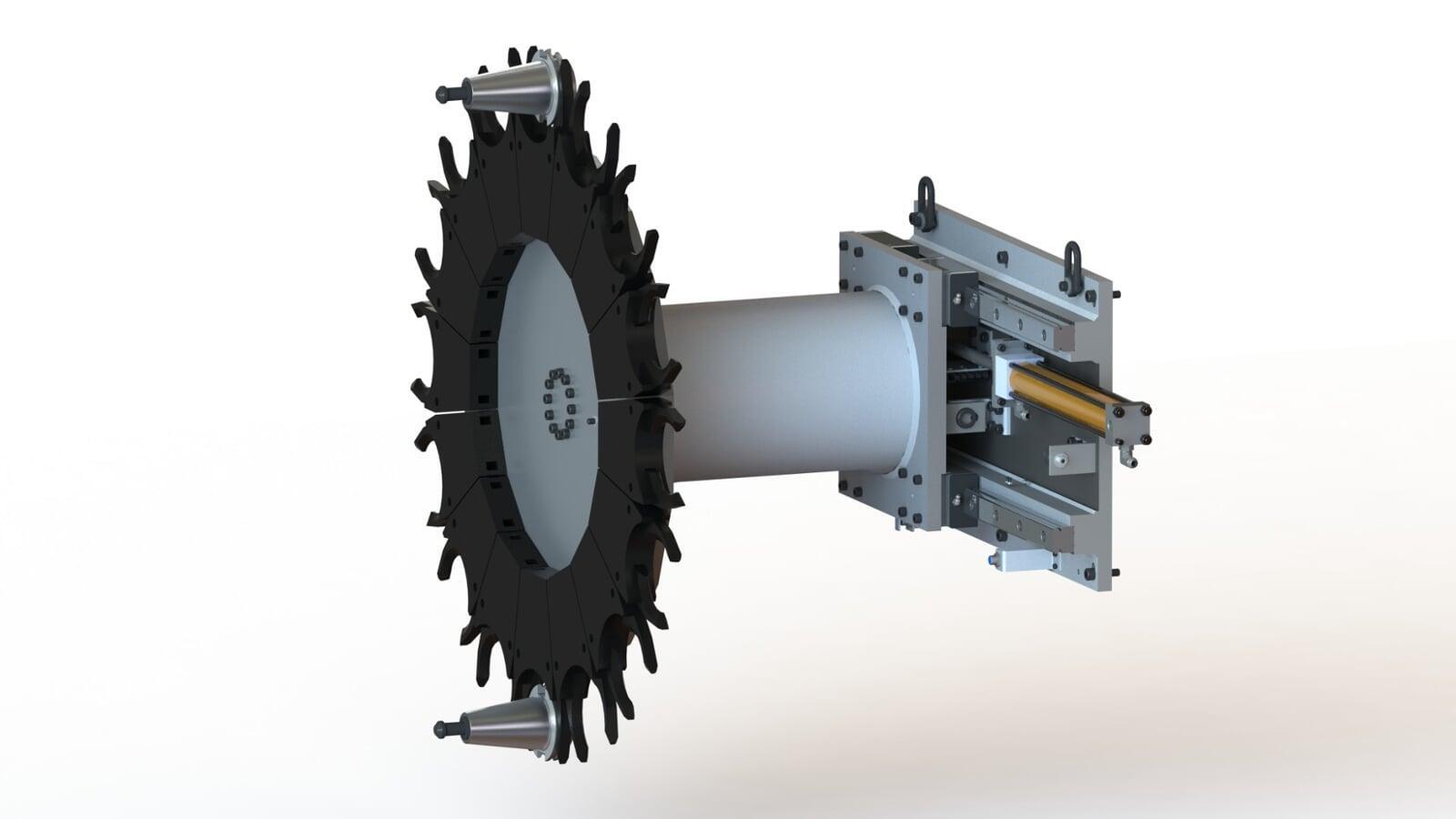

We can also upgrade worn out automation machines with new PLC controls, servo motors, AC motors, and mechanics to keep them running at optimal OEE's.

"I have been a supplier, and have worked for suppliers, in the industrial automation industry for over 10 years and I have rarely encountered a supplier with as much attention to customer satisfaction as Accelerated" - Engineer, Grundfos

In-House Repair Services

- Machine & Equipment Repairs

- Machine Upgrades and add-ons

- Ballscrew replacements

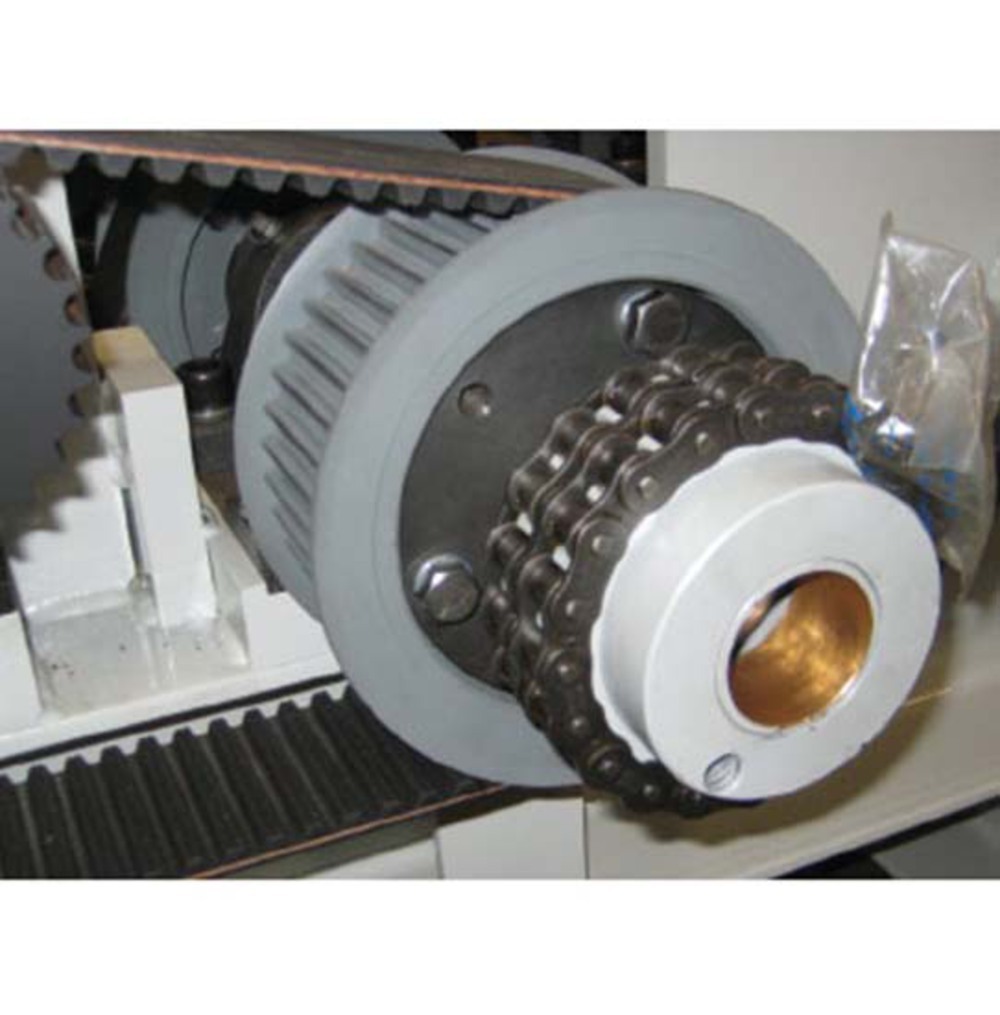

- Rack and pinion replacements

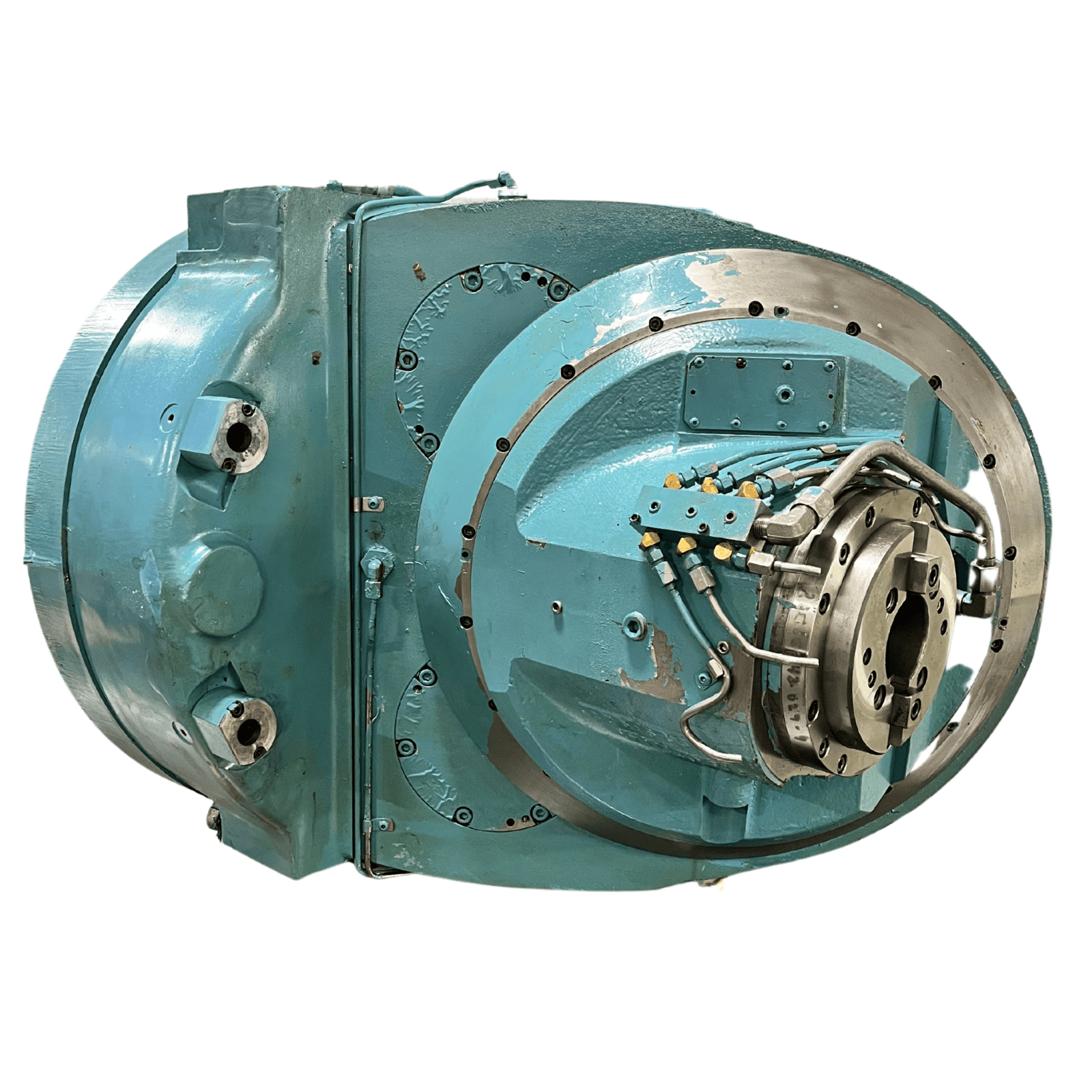

- Gearbox rebuilds

- Bearing and seal replacements

- Guideway replacements

- Way Scraping

- Turcite replacement

- Tool changer and chip conveyor repair

- Way cover repair or replacement

- Scale and Encoder replacement

- Reverse Engineering

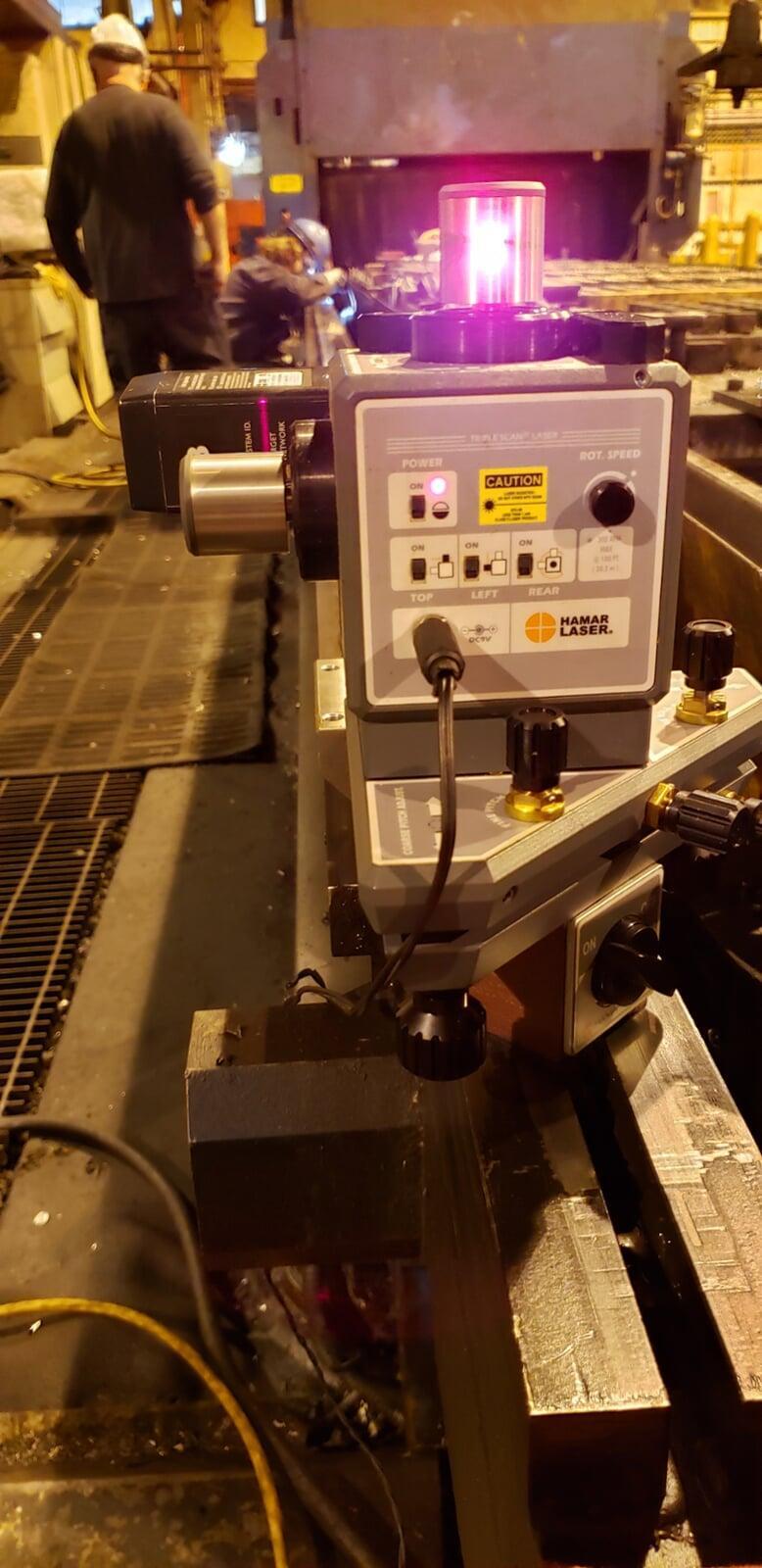

- Alignment and Calibration

Onsite Repair and Onsite Services

- Preventative Maintenance Programs

- Machine & Equipment Repairs

- Equipment Installation or replacement

- Drive System and Guide System repair

- Electrical Repair

- Machine Leveling & Alignment

- Hydraulic, Pneumatic, and Lubrication system repairs

- Pump and Motor replacement

Spindle Repairs

- Spindle repairs

- Motor and coupling repair

- Belt drive repair

- Rotary union repair

- Gripper repair and pull force repair

Electrical & Control Repairs

- Electrical and wiring repairs

- CNC and HMI Replacement

- Servo drive and spindle drive replacement

- Handheld pendant and push button repairs

- Safety Interlock Repairs

"We had a machine go down at the end of the shift on Friday night. I can't believe you had us up and running on a Saturday Morning. You saved our weekend shift!" - Plant Manager, Accuride

To get started simply submit a picture or description of your machine today for a quote or to schedule a consultation with one of our rebuild experts.

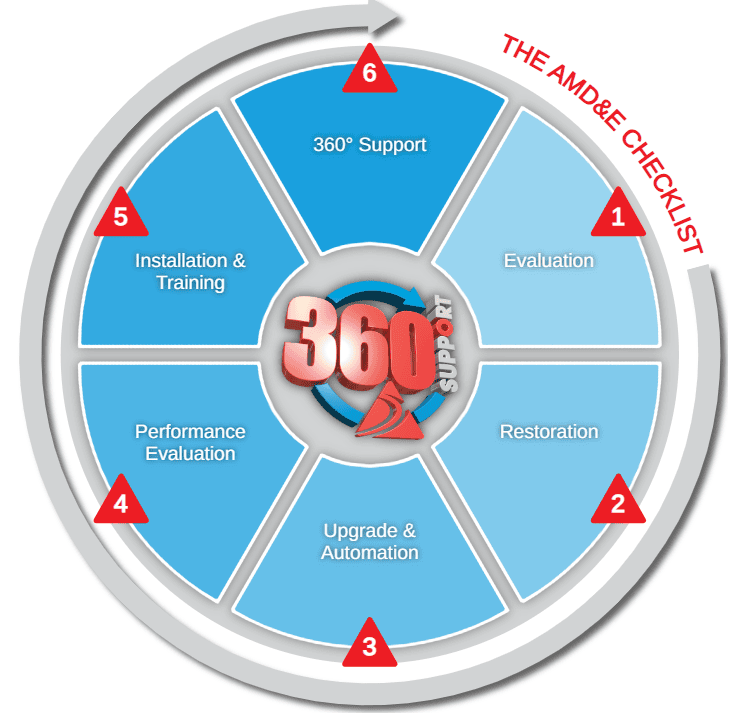

The AMD&E Checklist

The AMD&E checklist guides you seamlessly through the rebuilding process.

Step 1: Evaluation

- 360° assessment

- Evaluation report with pictures and summary findings

- Rebuild plan, itemized with costs and lead times

- Customer review

- Agreement & authorization to proceed

Step 2: Restoration

- Teardown & methodical cleaning

- Refurbishment & restoration

- Seal & bearing replacement

- Rebuild & replace worn or damaged components

- New paint & coatings

Step 3: Upgrade & Automation

- Drive train upgrades

- Lubrication automation

- Control system upgrades

- HMI upgrades

- Sensor installation

- Safety Integration

Step 4: Performance Evaluation

- Alignment & geometry certification

- Systems checkout

- Calibration

- Run-in & stress test

- Factory acceptance test

Step 5: Installation & Training

- Delivery

- Installation

- Training

- Site acceptance test