Manufacturing Services

Specializing in precision CNC Machining, Fabrication, and Precision Assembly for quality driven industries including Space, Aerospace, Defense, Power, Energy, and more.

Manufacturing

AS9100D and ISO9001 Quality Management System embracing lean and continuous improvement.

The Accelerated Machine Design and Engineering production control system has been engineered and optimized to serve the Space, Defense, and Aerospace communities.

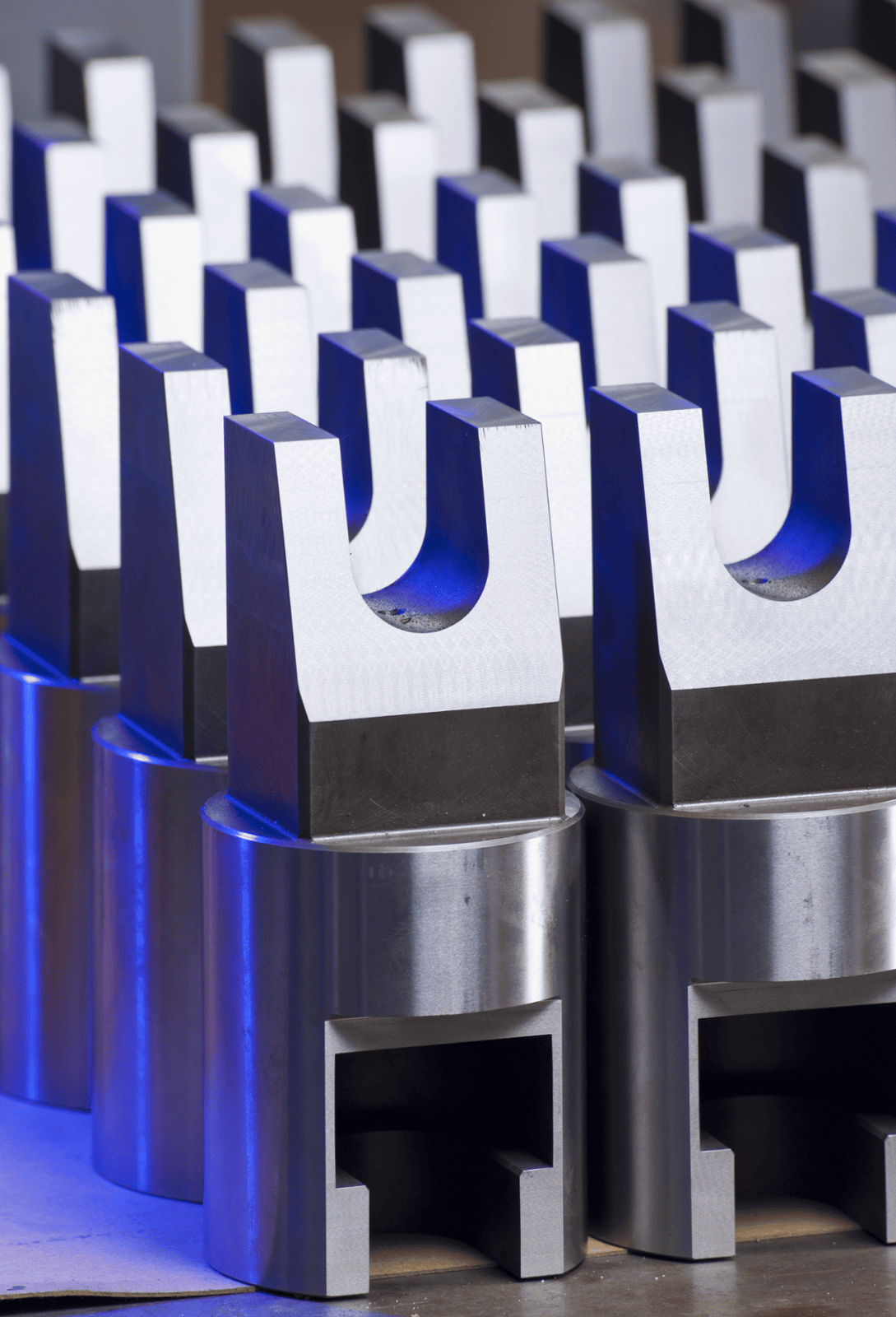

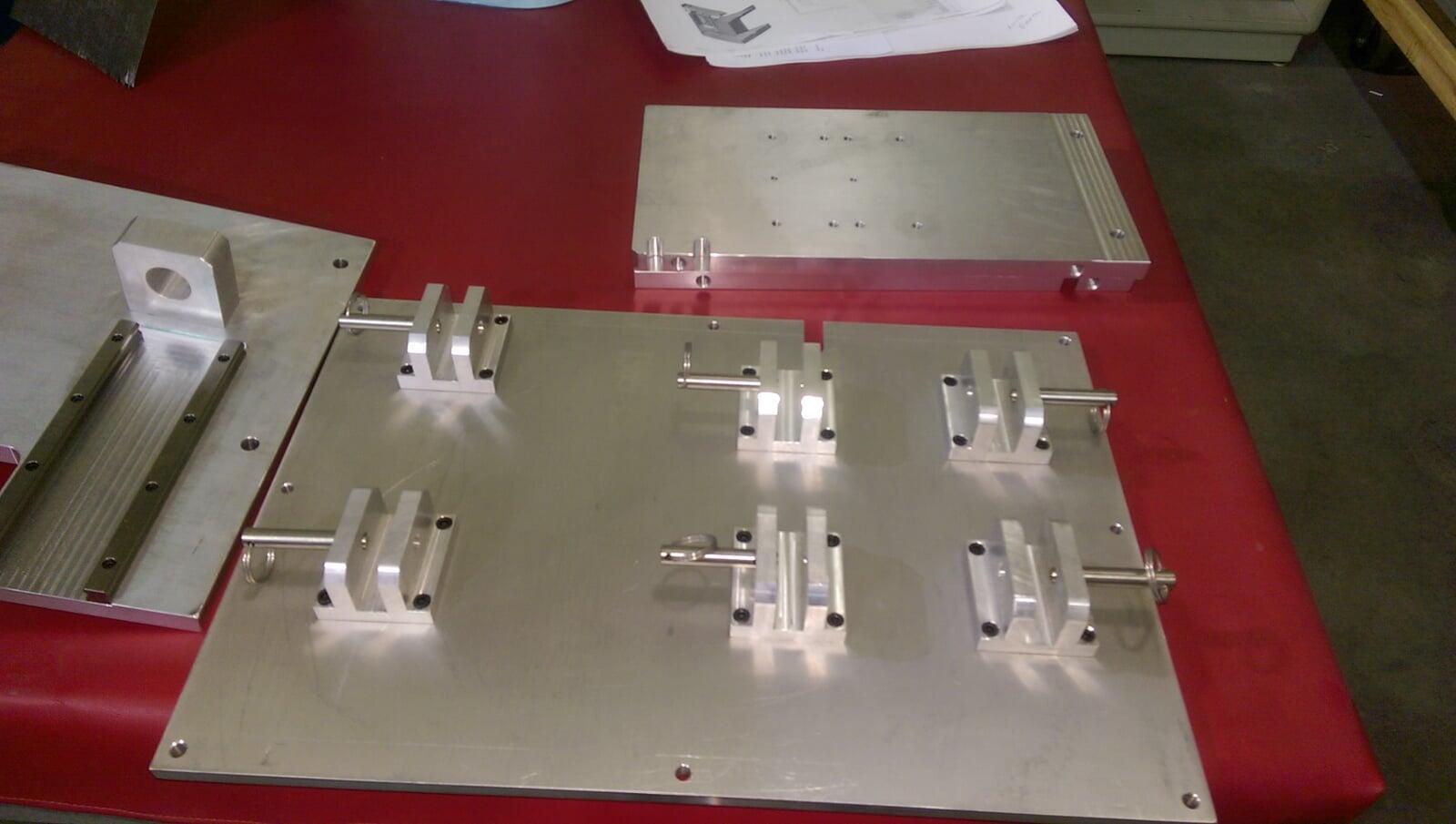

CNC Machining

- 3, 4, and 5-Axis Machining. 5-Face Bridge Mill Machining

- Prismatic Machining from 0.5" Cube up to 120" X 60" Foot Print

- CNC Machining of Castings, Forgings, Stampings

- CNC Machining of Weldments and Fabrications up to 120" X 63" X 48"

- Match Machined Housings, Thin-Walled Aero & Space Structures, Light Weight Structures, High Temperature Alloys, Motion Control Components, Optical Components

- Weldment machining, Base machining, Frame machining, Ground Plate machining, Platten machining, Mold Base machining

- CNC machining of Gun Drilled Housings, Gun Drilled Tombstones, and Hog Outs

- Materials include Aluminum alloys, stainless steel alloys, titanium alloys, Steel & tool steel, brass, plastics, and other engineering materials

- CNC Machining of Tight Tolerance & Precision Parts

- Robotic Machine tending for lights out production

- Machine tool precision, Aerospace CNC Turning quality

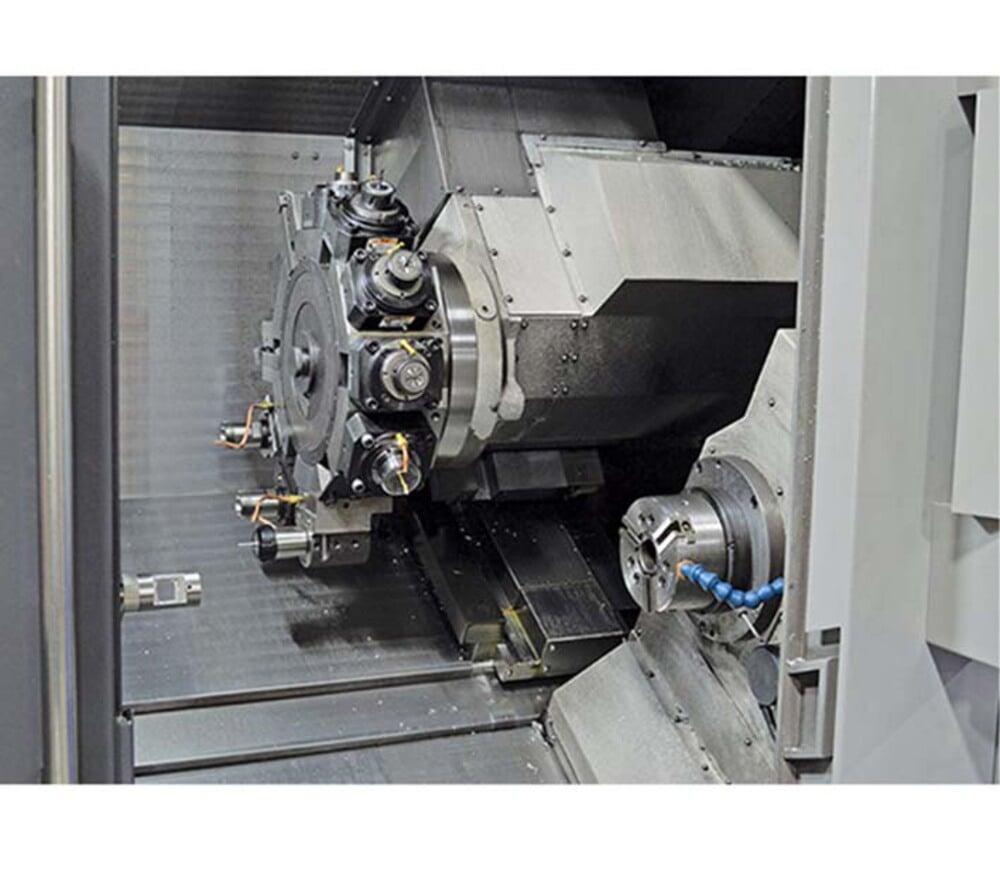

CNC Turned Parts

- CNC Turning for part sizes from 1" diameter to 16" diameter

- CNC Mill-Turned parts up to Ø8" (Lower Volumes Ø12")

- CNC Turned Chucker Parts & Done-in-one

- Sheaves, Couplings, Adapters, Flanges, Housings

- Aluminum alloys, stainless steel alloys, titanium alloys, Steel & tool steel, brass, plastics, and other engineering materials

- Bar-feeding and robotic machine tending for lights out production

- Machine tool precision, Aerospace CNC Turning quality

Precision Honing, Grinding, and Finishing Operations

- Surface Grinding – Up to 24" Long X 12" Wide Parts

- Rotary Surface Grinding – Up to Ø16" X 2" Thick parts

- ID and OD Grinding

- Materials include Steel alloys, Aluminum alloys, Titanium, Inconel, Hastelloy and Stainless Steels, Brass, Bronze, and other materials

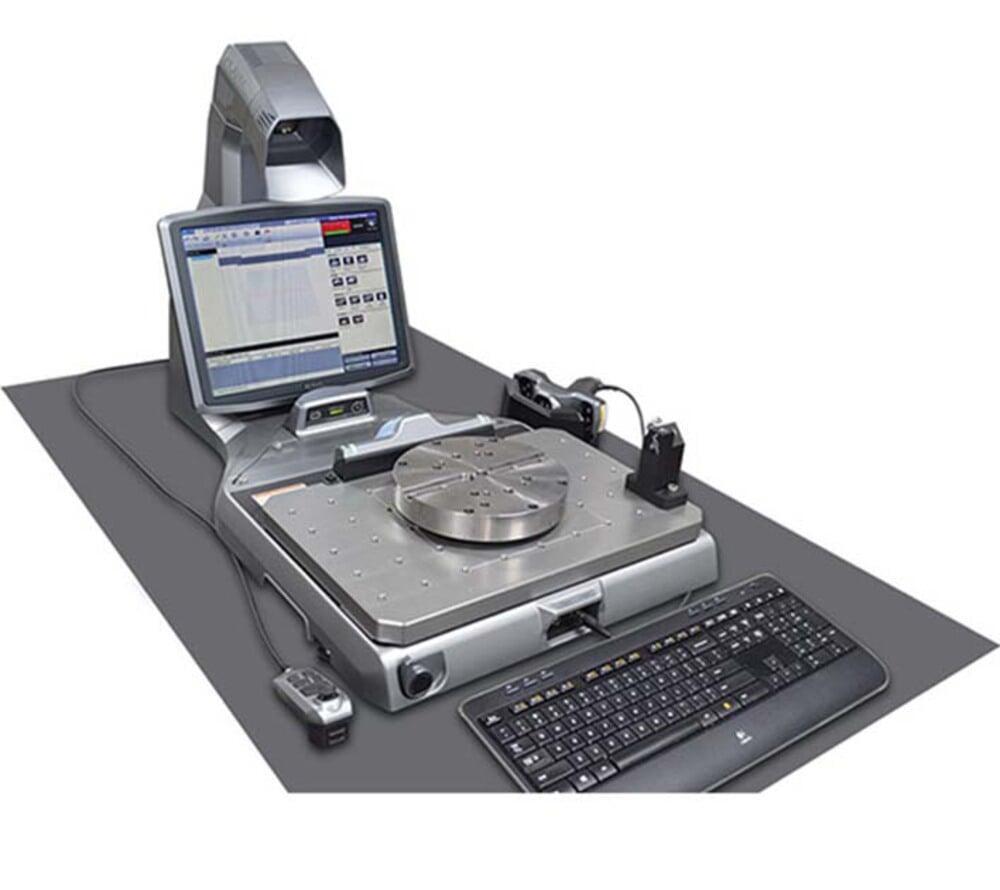

Inspection

- First Article Inspection, Quality Plan, PPAP, and Production Inspection according to MIL-STD-105D.

- Manual CMM Inspection for quick verification

- Portable Micro CMM Inspection for quick verification & high accuracy. Used to confirm tight tolerance machining for prismatic parts.

- Portable Large format CMM Inspection – up to 30' work zone

- Automated CMM for production inspection

- Manual Inspection - Surface Gauges, Micrometers, calipers, surface gauges, height gauges, profilometers for surface finish inspection

- Hardness Inspection

- Inspection for space, aerospace, and defense industries on AS9102 form

Laser Marking

Laser marking is an excellent method for labeling parts or assemblies. Enhance your product's finish with laser marking—perfect for adding serial numbers, part numbers, or other identifiers like labels, images (in 2D and 3D), and wrap-around designs. Works effectively on steel alloys, aluminum alloys, and most plastics.

Secondary Operations

AMD&E leverages a robust supply chain managed by an AS9100D quality management system to provide total solutions for part and assembly manufacturing. Supply chain includes solutions for:

- Anodize - Type II (sulfuric) and Type III (Hard Anodize)

- Passivate, Chem Conversion Coating, Zinc, Electroless Nickle, Black Oxide, Chrome

- Shot Blasting and Abrasive Blasting

- Paint and Powder Coat

- MPI, NDT

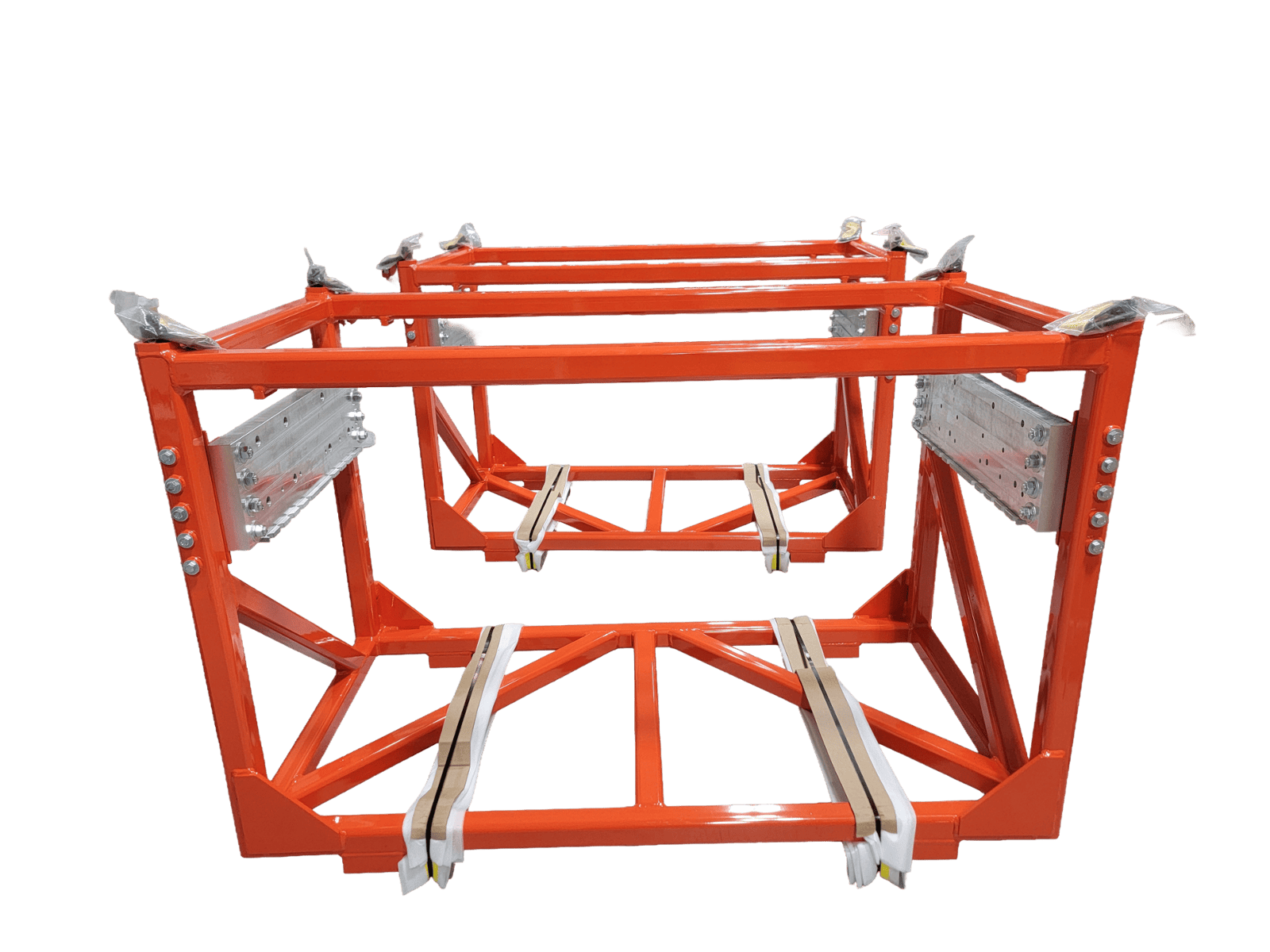

Fabrication & Welding

Precision Fabrication & Welding Services

From concept to completion, we deliver high-quality metal fabrication and welding solutions. Our capabilities include:

- Cutting, Bending & Forming – Precision shaping for sheet metal and heavy plate projects.

- Sheet Metal Fabrication – Custom components with tight tolerances.

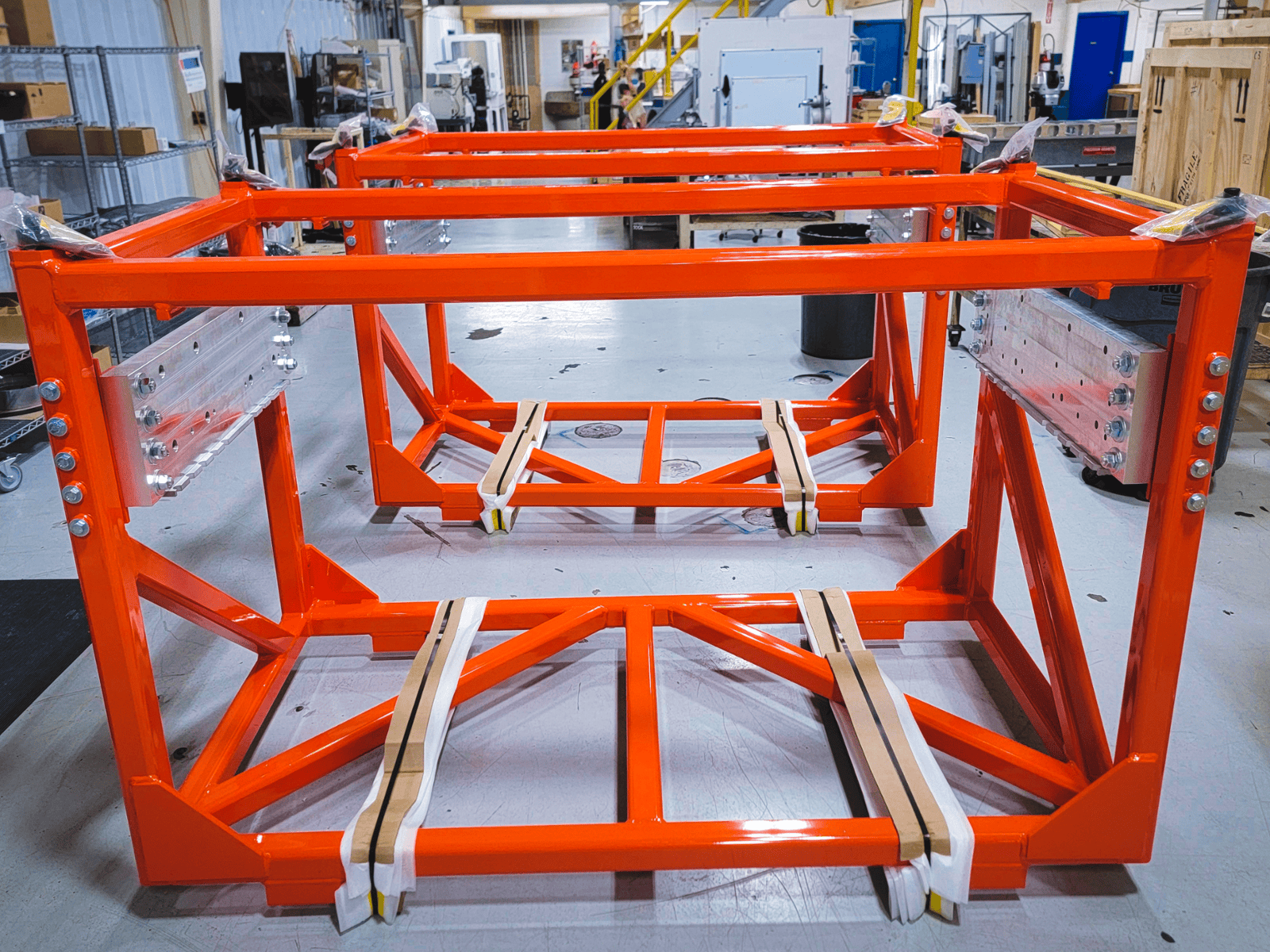

- Structural Weldments – Weldments comprised of tube, I-Beam, C-Channel, Angle Iron, and other structural profiles are a core competency.

- Heavy Plate Fabrication – Heavy weldments for Machine tools, Presses, and other industrial equipment.

Additional Welding Capabilities:

MIG, TIG, and Laser Welding ensure strength, precision, and efficiency for every project.

Trust Accelerated for craftsmanship, reliability, and on-time delivery.

Assembly

At AMD&E, we deliver top-quality precision mechanical, electrical, and electromechanical assembly services by combining the craftsmanship of highly skilled technicians with proven processes and cutting-edge technology. For customers in industries such as space, defense, energy, and biotech, this level of precision isn’t just a benefit, it’s a necessity. Whether it’s ensuring aerospace components perform flawlessly in extreme environments, supporting mission-critical defense systems, driving efficiency and reliability in energy infrastructure, or enabling breakthroughs in biotech research, our commitment to accuracy and innovation empowers customers to achieve ambitious goals with confidence. When companies hire AMD&E they gain a trusted machine builder dedicated to excellence, reliability, and advancing the frontiers of technology.

Mechanical Assembly

Mechanical Assembly and machine building is a core competency. Put us to work when you need precision and accuracy. Our build team is comprised of assemblers, machine builders, millwrights, and industrial maintenance mechanics. We can assemble, install, and align precision equipment on time, on budget, and within spec.

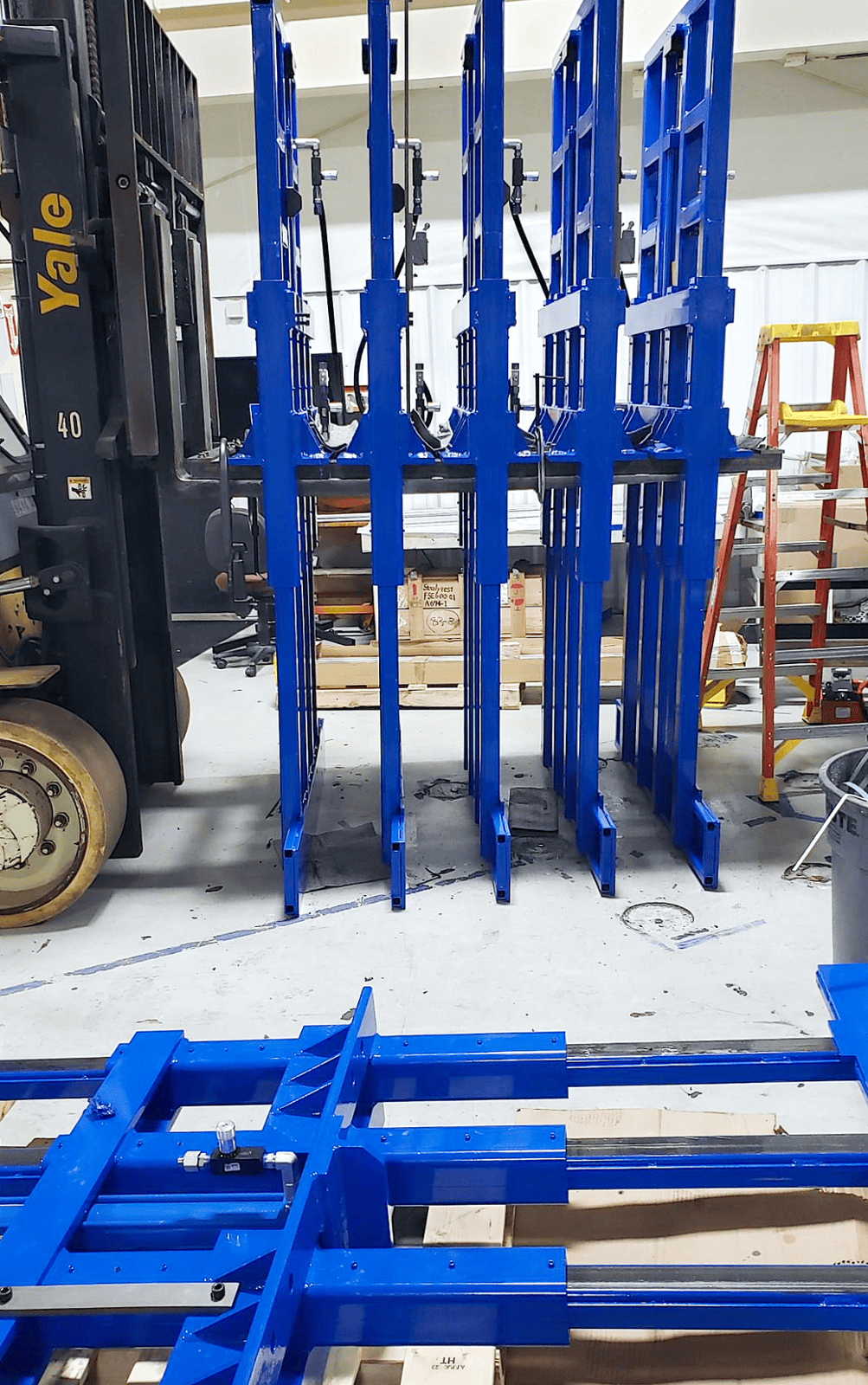

Assembly Services - Precision Machine Builds

Complete Build to Print service. Includes mechanical alignment, precision fitting, complete inspection. Ability to handle all aspects from procurement, to fabrication, machining, assembly, and alignment.

Sub Assembly Services

Installation of precision guide rails for a specialed machine.

Mechanical Assemblies, Fixtures, and Tooling

At AMD&E, we specialize in precision mechanical assembly where maintaining exact parallelism, perpendicularity, and spacing is absolutely critical to performance. Our skilled team ensures that every component is aligned to the highest standards, delivering assemblies that meet the demanding tolerances required in advanced industries. To guarantee accuracy, we utilize a portable Coordinate Measuring Machine (CMM), providing on-site validation that all build specifications have been achieved. This rigorous approach not only ensures compliance with design requirements but also gives our customers confidence that their assemblies will perform reliably in mission-critical applications. By combining craftsmanship with advanced metrology, AMD&E delivers mechanical assemblies that set the benchmark for precision and quality.

System Builds

System build to print services for Military, Defense, and Space industries. With complete inspection reports, material certifications, and Certificates of Conformance.

Heavy Machine Builds

Hydraulic System Builds

High Volume Builds

- Inventory & stocking of components

- Testing, documentation, and compliance

- Certifications (UL, CE, TUV, etc.)

Automation Machine Builds

Our team provides build-to-print services for automation systems and automation machines. Portfolio includes assembly machines, pick-and-place machines, robotic systems, sorting, packaging, inspection, and many.

Electrical Assembly

Our Electrical Assembly team delivers high‑quality electronic assemblies, machine wiring, and custom electrical panels. Every technician is trained to NFPA79, NEMA, NEC, and OSHA standards, ensuring safe and compliant workmanship. The result is a clean, labeled, fully tested product that reflects true craftsmanship.

Electrical Cabinet Assembly and Wiring

With decades of expertise in assembling and wiring control systems, electrical cabinets, panels, and embedded systems, our team of skilled technicians and machine builders delivers high-quality, fully finished systems ready for installation.

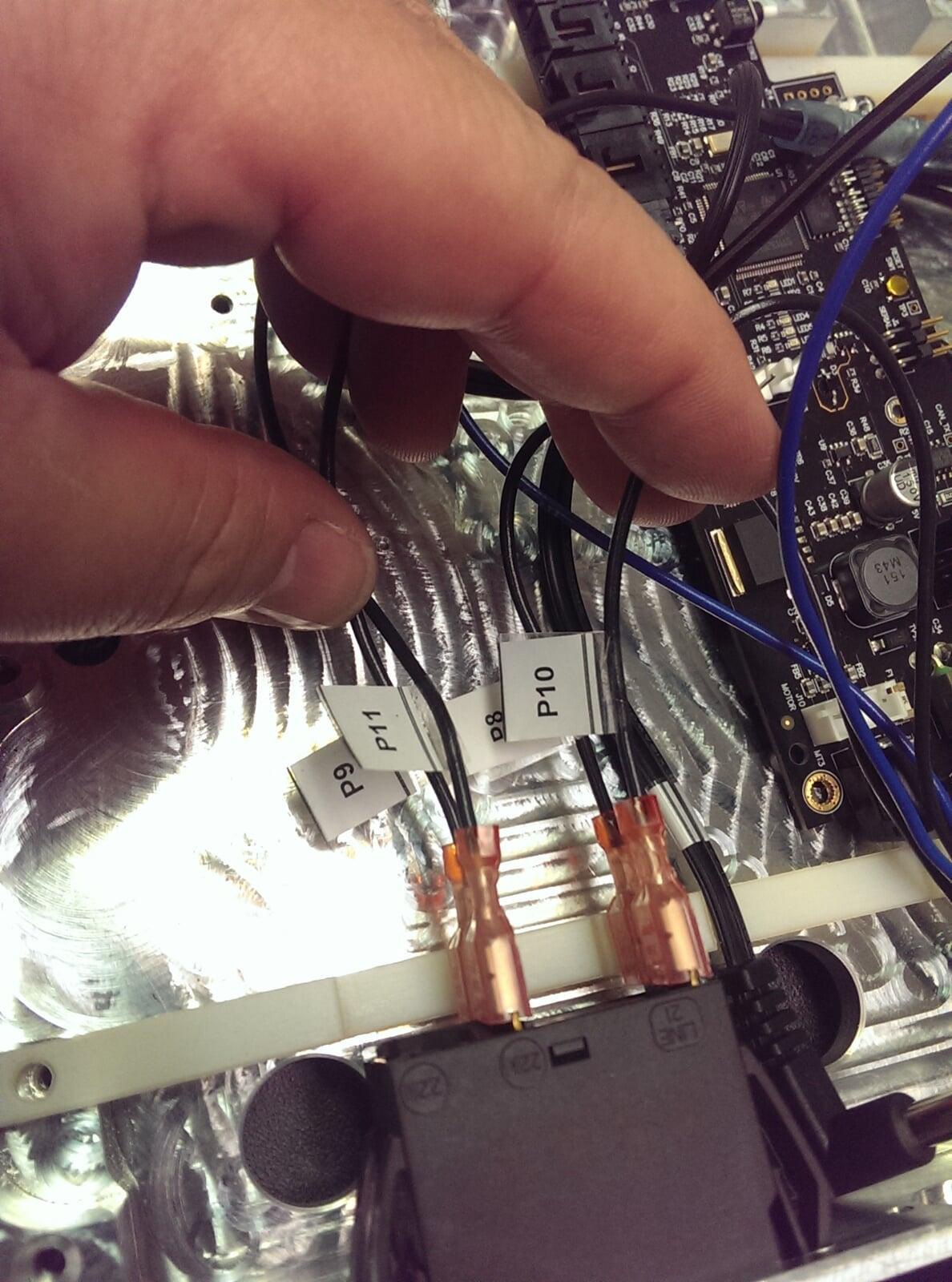

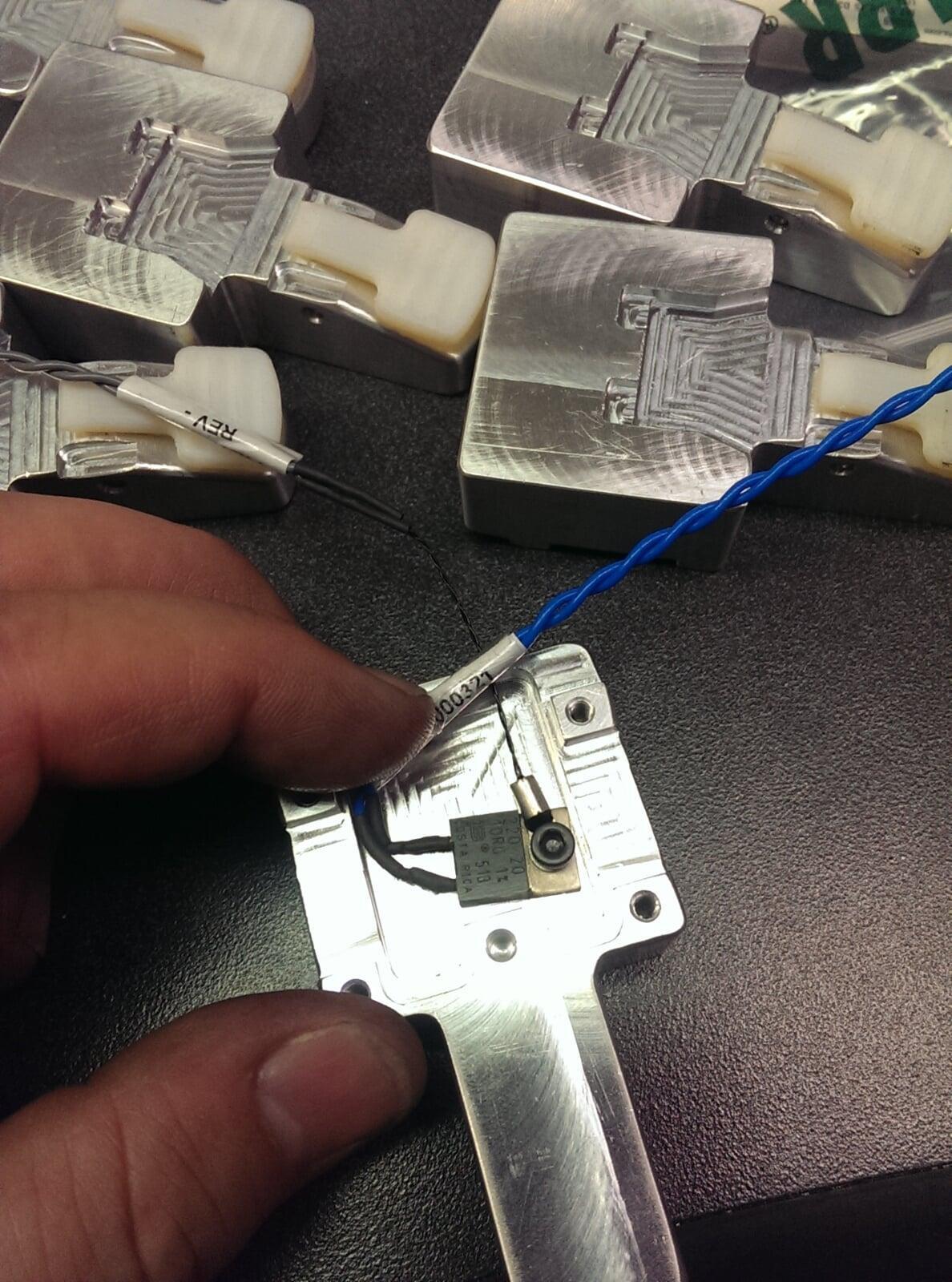

Electrical Device Wiring

Our Electrical Assembly capabilities cover a wide range of advanced solutions, including industrial automation panels, HMI cabinets, and fully customized embedded systems built with precision PCBs and connectors. Each assembly is designed and manufactured to meet the highest standards of reliability and performance, ensuring seamless integration into complex operations. Whether it’s powering automated production lines, enabling intuitive operator interfaces, or supporting specialized embedded applications, our assemblies are tailored to deliver efficiency, durability, and innovation. By combining technical expertise with flexible customization, we provide customers in demanding industries with electrical systems that not only meet specifications but also drive productivity and long-term success.

Electrical Push Button Assemblies

Leading provider of automation assemblies, including push button systems, for both automated and semi-automated applications.

Electrical Assembly and Wiring

We offer comprehensive electrical services such as wiring, assembly of electrical components and embedded systems, wire labeling, ferrule installation, laser marking, heat shrinking, connectorization, and continuity testing.

AS9100D & ISO9001 2015 Certified for Machining, Assembly, and Engineering

On Time Delivery

DFARS Material

DPAS DX-A1 Experience

Material Certifications

NADCAP Supply Chain

First Article Inspection

Certificate of Conformance

AQL & MIL-STD-105D

FOD Prevention Program

Workforce Training Program