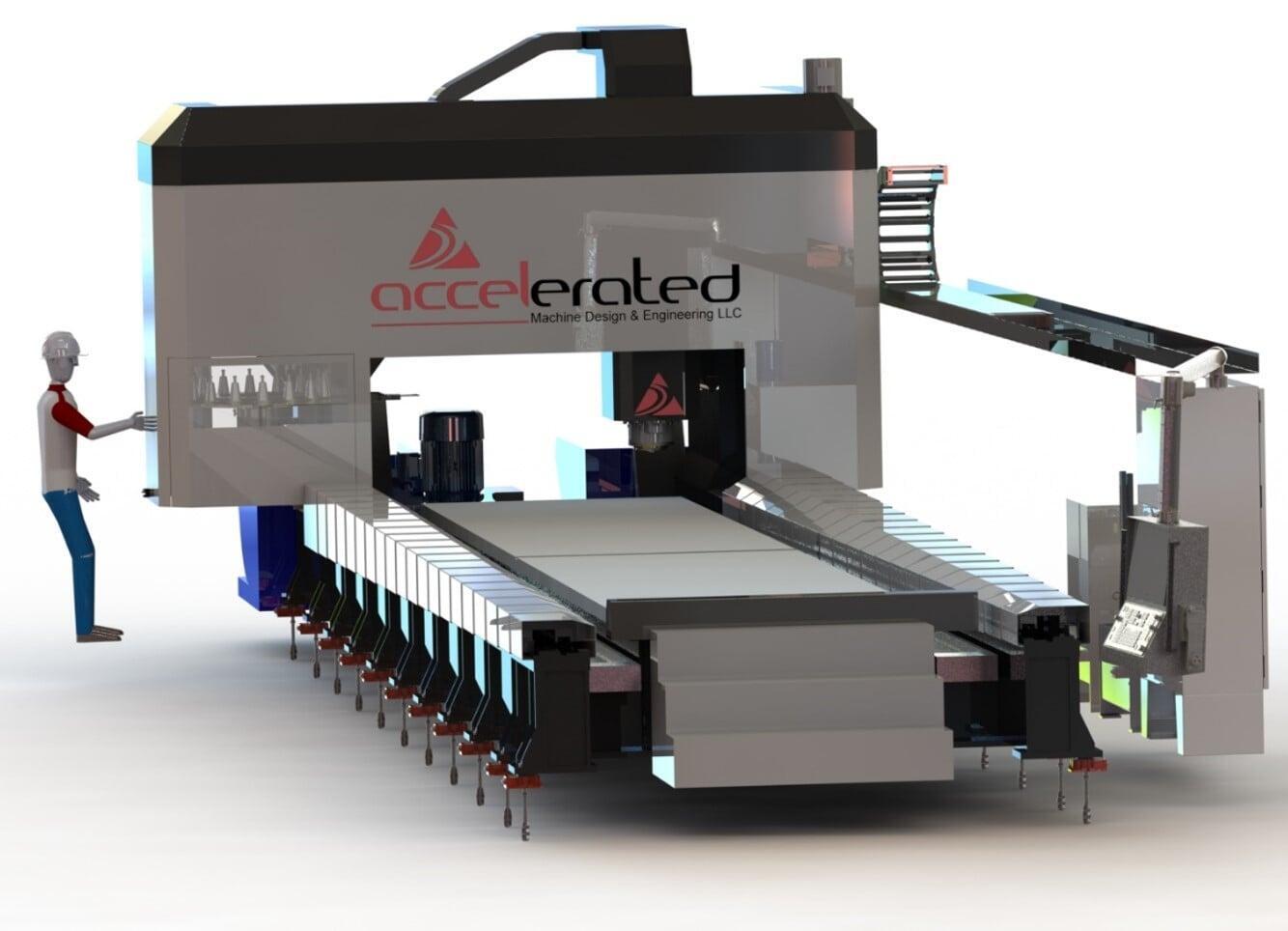

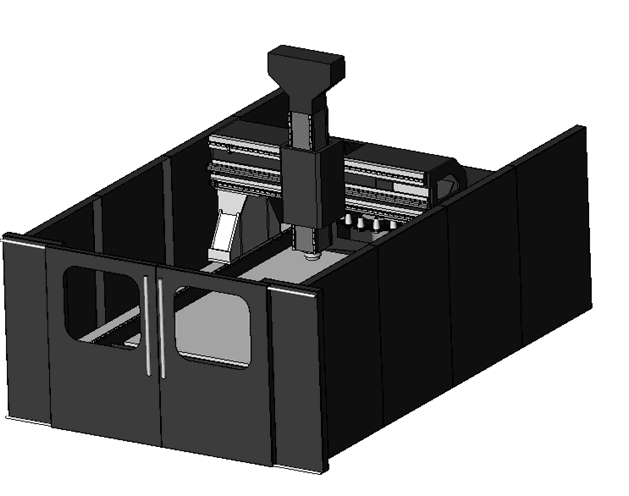

The Metal Max CNC Gantry

Your American Made Plate Mill!

Powerful Productive Performance. They don't build 'em like this anymore

💥 High power, high-torqe spindle ⚒ for heavy milling of steels, irons, and hard metals

🎯 Better accuracy and repeatability from direct drive technology and absolute encoders on all axes

💪 Higher metal removal rates possible through rigid machine architecture, and heavy duty drives

⚡ Better Surface Finishes from best technology in the industry

⏱️ Low Process Times, High Throughput from higher rapid feeds and accelerations

💲 Trustworthy Reliability. Consistent performance allows you to make money on tough jobs

⚙️ Easy to maintain. Preventative maintenance programs keep you running

♻️ Efficient chip removal with large dual chip conveyors and optimized chip collection.

🏗 Compact machine footprint for a large gantry. More X-axis travel in the same footprint as other bridge mills and portal machines

| Available | Travels | Feed rate | Feedback | ||

| Axis | Min | Max | Standard | Optional | TYPE |

| X-Axis | 2M [40"] | 20M** [787"] | 20m/min [787ipm] | 25m/min * [1000ipm] | SCALE |

| Y-Axis | 1M [40"] | 3M** [118"] | 20m/min [787ipm] | 25m/min * [1000ipm] | SCALE |

| Z-Axis | .5M [45"] | 2M** [80"] | 20m/min [787ipm] | 25m/min * [1000ipm] | SCALE |

| Optional A-Axis | +/- 105° | 30 RPM | 60 RPM | Encoder | |

| Optional C-Axis | +/- 360° | 30 RPM | 60 RPM | Encoder | |

| Optional Rotary Table | Ø.5M [20"] | Ø2M | 120 RPM | 200 RPM | Encoder |

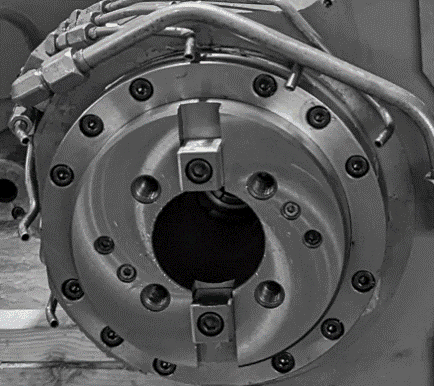

High Torque Metal Max Spindle

Torque: 2200Nm (1623 ft*lbs)

Speed Ranges:

⬇Low Speed Range:0 to 400RPM

⬆High Speed Range: 0 to 4000 RPM

5000 RPM S3 Rating

Torque:

- Low Speed Range:

- 1300Nm (960 ft*lbs) @450 RPM•2200Nm (1623ft*lbs) @300 RPM

- High Speed Range:

- 325Nm (240 ft*lbs) @ 2000RPM

- 200Nm (150 ft*lbs) @ 3000 RPM

- 125Nm (92 ft*lbs) @ 5000 RPM

High Power Metal Max Spindle

Power: 75kW (100hp)

Speed Ranges:

Torque:

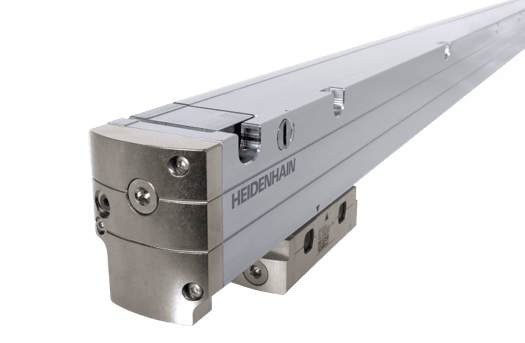

Linear axes utilize absolute encoders. This eliminates the need for homing each time the machine is powered on and reduces the time required to reach production each day.

Thermal expansion of long axes due to temperature changes in your facility are minimized by using scale encoders on each linear axis.

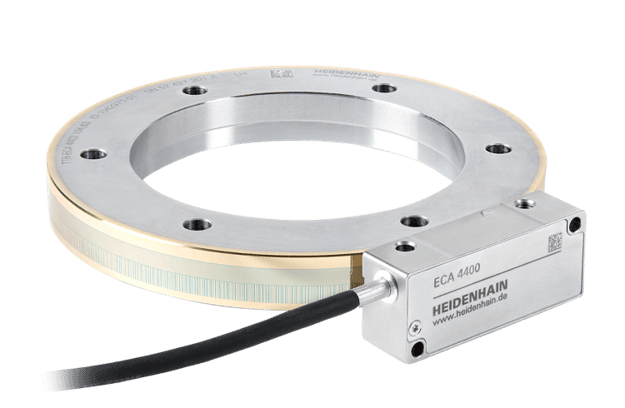

Rotary Axes are directly coupled to ECA4000 encoders with high accuracy and large diameters for higher resolution. 25,993 lines per revolution along with advanced encoder interpolation allow for high dynamic response.

With these advanced features, the Galaxy stands out as one of the most precise large machines available for production today.

The Galaxy’s innovative Direct Drive motors are engineered to reduce maintenance and wear commonly found in conventional gear or belt drives, boosting rotary acceleration and enhancing spindle positioning by eliminating any lost motion caused by backlash.

Experience the holding power of the Galaxy A and C axis hydraulic clamps, providing exceptional clamping force for locking in place during heavy cuts. Unlike traditional Hirth couplings, our hydraulic clamps allow for infinite clamping at any orientation, without the limitations of fixed degree increments. Maintenance-free and long-lasting, our A and C clamps offer durability and reliability.

Liquid-cooled motors and liquid cooled head frame ensure thermal stability, while delivering superior accuracy, outperforming the competition. Elevate your manufacturing process with our advanced technology and precision engineering.

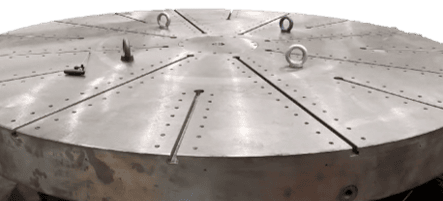

Make round parts? Add an Optional Rotary Table

3 Rotary Modes, 1 Machine!

Experience the versatility of the Galaxy with 3 Rotary Modes in 1 Machine.

The powerhouse rotary table is designed to handle large rings with diameters up to 7500mm (295” or 24’). The rotary table ensures precise milling, drilling, and turning operations of large diameter rings or round parts.

Milling Mode securely clamps the rotary table, guaranteeing the rigidity necessary for accurate milling and high-speed machining.

In Turning Mode, the Galaxy transforms into a VTL, offering options to operate in constant RPM mode or constant SFM mode.

Utilize Mill-Turn Mode for effortless indexing of parts or achieve exceptional interpolation with the Table axis integrated within the interpolated path.

Our rotary table effortlessly accommodates parts weighing up to 30,000kg. Thanks to the temperature controlled base, thermal expansion is minimized, ensuring stability and precision during extended, heavy-duty cutting operations. With a lubricated bearing and gear system, longevity and durability are guaranteed.

The best machine builders in industry bring their years of machine tool experience to ensure each system is the highest quality possible.

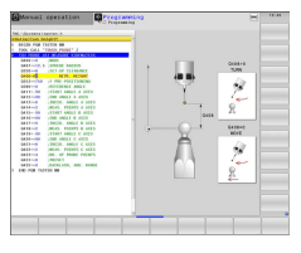

The Latest CNC Technology

The Galaxy is ready to revolutionize the future with its cutting-edge Siemens SinumerikOne or Heidenhain TNC 7 CNC controls.

Experience advanced features like chatter and vibration reduction, along with faster accelerations for enhanced part production and superior surface finishes. Achieve precise volumetric accuracies thanks to integrated CNC, servo drives, and feedback scales.

A 24” touch screen enhances operator efficiency by presenting programs, process data, and graphics in a user-friendly layout. Customize the screen to suit individual preferences for an optimized user experience such as left-hand or right-hand screen layout or dark mode. Safeguard against collisions and mishaps by simulating toolpaths on the HMI. The state-of-the-art conversational tool & material library ensures quick and easy programming when offline CAM systems are impractical.

Hand Pendant for the control you need

With a Hand Pendant that functions seamlessly throughout the workzone, setup and first part runoff become effortless.

Embrace the advanced control system and unlock next-generation results.

Kinematics Optimization for 5 Axis head

Automatic probing compensation to calibrate rotary head axes. Tremendous improvement over Fanuc kinematic setting.

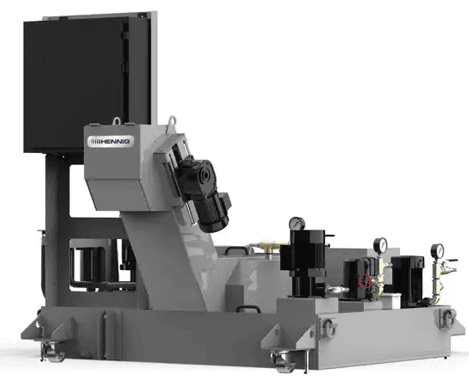

Exclusively with Hennig Chip System

The Galaxy’s Hinge Belt chip conveyor system stands out as the top choice on the market for handling a wide range of materials. While it may come at a higher price point compared to chip flumes or augers, it proves to be a valuable investment for job shops that work with diverse materials.

Utilizing high-pressure thru-tool coolant not only enhances tool longevity but also significantly boosts Material Removal Rates (MRR) compared to systems lacking this feature. Moreover, it enables precise deep hole drilling with the use of thru-tool coolant.

Implementing advanced filtration technology results in cost savings by reducing filter element maintenance expenses, prolonging coolant lifespan, and cutting down on tool and coolant expenditures.

The system’s below-floor design not only enhances reliability but also minimizes maintenance requirements, offering a seamless and efficient operation.

80 Pocket Tool Changer

Increase walk away time with additional cutting tool storage. Load duplicate tools for lights out machining.

AC Head

2-Axis head to provide continuous 5 axis machining or 3+2 heavy duty machining. Features direct drive torque motors, water cooling, and feedback scales

Part Measurement Probe

Reduces set up time, scrap rate, and ensures part quality prior to work pieces being removed from the machine

Tool Length Measurement Probe

Measure tool length without touching off on the part. Eliminate crashes and scrapped parts due to incorrect tool length

High Pressure Coolant System

Unlock improved material removal rate, improved chip evacuation, and increased tool life through use of high-pressure tool coolant. Recommended for drilling applications to improve chip evacuation in holes. This option in conjunction with Through Spindle Coolant option is recommended for hole making machines. This option includes 1000PSI pump, 8 GPM Brinkman Pump and cyclonic filter.

Dual Hinge Belt Chip Conveyors

Upgrade from chip flushing to a chip conveyor. The hinge belt conveyor is a proven heavy duty conveyor solution for a variety of materials, chip types, and chip loads. Includes Variable Frequency Drives that prevent overloads due to chip jambs. This option also includes a jamb recovering reversing feature to reduce the time required to recover from chip jambs.

Disk Filtration

MReduce your downtime due to coolant issues and reduce your filter element cost by adding the disc filtration system. The disc filter includes a micronic weave stainless steel permanent media filter and a backwash manifold. This option improves coolant performance and extends the life of media filters. This reduces your operating cost and reduces the amount of maintenance required for the coolant system

Work Zone Lighting

Add Enclosure and Cross Rail Lights to illuminate work zone and spindle. Heavy duty LED lights are IP67 and engineered to reduce chip impact and coolant exposure.

Mist Collector / Smoke Extractor

Capture and clean airborne mist and smoke and prevent smoke and mist from filling your factory. This option improves air quality in your factory and extends the life of the machine by reducing contamination on the surfaces of way covers and machine components

Conversational CNC

Conversational Tool and Material Library. Simulate tool paths on the HMI to prevent collisions and crashes. Generate programs quickly from 2D and 3D Geometry

Tool Breakage Detection

Rapid capacitive tool breakage detection allows for fast tool monitoring for overnight runs or lights out production, without the time-consuming length measurements

Vison Tool Inspection

Save time during tool inspection without removing the tool from the machine or tool magazine. Instead, simply perform your inspection on the control. Software options let you perform inspections at a later time, even to some extent offline. The camera takes close-up images of each tooth as well as detailed panoramic images of the entire tool circumference.

Spindle Camera

Self cleaning camera with integral lighting. Mounted to focus on the cutting tool from above the work zone. Not available with all spindle and head combinations

Thru Spindle Coolant (TSC)

Recommended for hole-making applications. This option increases tool life and improves MRR by improving chip evacuation and eliminating double cutting of chips

Oil Skimmer

Extend the life of cutting tool coolant and improve spindle life by adding an oil skimmer to the coolant system. The Oil Skimmer option removes oil and sludges from coolant with a disc skimmer

Coolant Monitoring System

Notify operators of non-conformances with the coolant system by adding his option. Low & high level detection, dirty filter detection, and tank temp detection are added with this option. Notifications and warnings are displayed on HMI

Thermal Stabilization Package

Reduce spindle and machine growth and reduce machining variation with this option. Thermal Stabilization package includes a spindle chiller, spindle cooling circuit, drive cooling circuit, and coolant chiller for the coolant tank and filtration system. This option also extends the life of coolant by reducing the losses due to evaporation

AutoLube System

Lube system dispenses an optimized amount of grease to each machine component to extend the life of the machine. Auto lube system includes grease pump, plumbing, and felt gears for rack and pinion drives. Low grease alarm notifies the operator when it’s time to replenish grease cartridges. Designed for greases up to NLGI 2

Retractable Top Enclosure

Enclose the entire workzone with a retractable top enclosure