YOU CAN HAVE IT ALL

AMD&E designs reliable machine tools and automation solutions tailored to our specific needs We listen, identify the problem, and develop a long life solution that achieves faster throughput, lower cycle times, greater profits and most importantlv a better bottom line.

BETTER BY DESIGN

Having a custom solution tailored to your specific needs is what sets AMD&E apart from buying OEM equipment out of a catalog. Our solutions are developed to enhance the way you work. Compared to OEM solutions that require you to change your process to fit the capabilities of their equipment.

CUSTOMIZED SOLUTIONS, ROCK SOLID RELIABILITY

Having a custom solution does not mean you have to make sacrifices. AMD&E builds rock solid, reliable solutions. We back them up with excellent customer service, industry-leading maintenance, and spare parts programs to provide an ownership experience customized to your specific needs.

ESSENTIAL USA MADE MACHINERY

Best of all, our equipment is made in the USA by skilled professionals that treat every machine as if it is going into their own shop. We don't rest until we've delivered the best!

"We didn't think it was possible to find a machine with all of the features that we needed. We were thrilled that Accelerated could design a machine that solved our production challenges and fit our budget. Buying a machine custom designed for our product has resulted in better part quality and lower cucle times than we thought were possible. The machine paid for itself in less than two years."- President, Firearms Manufacturer

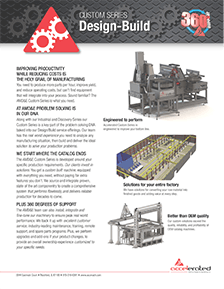

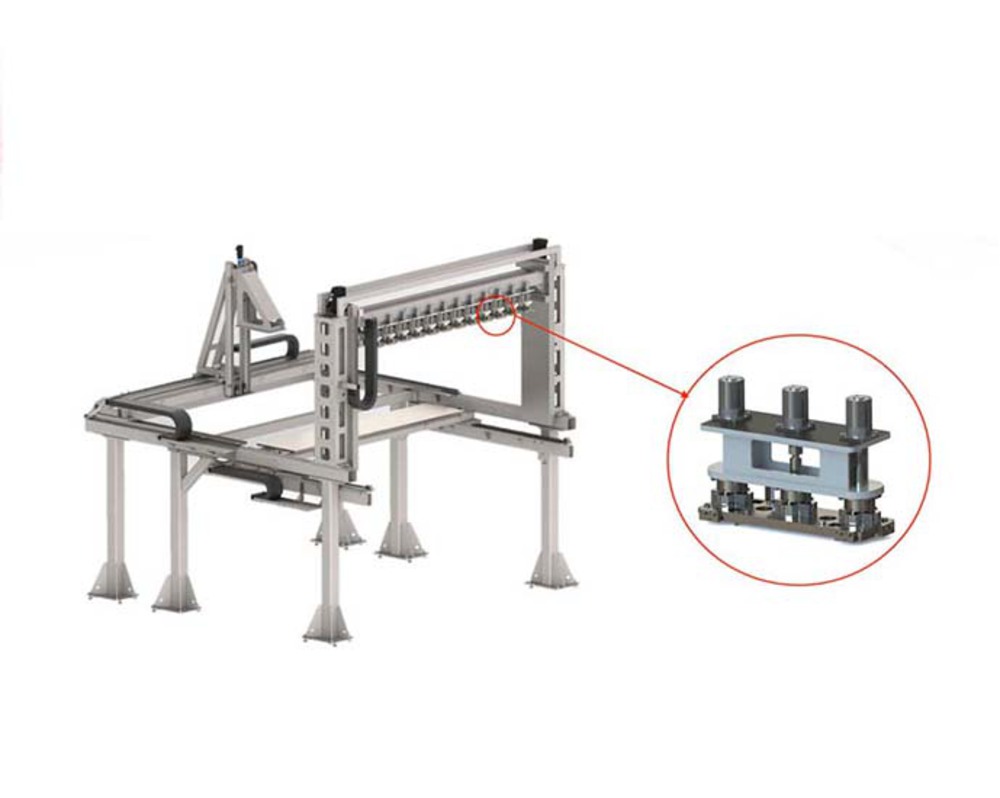

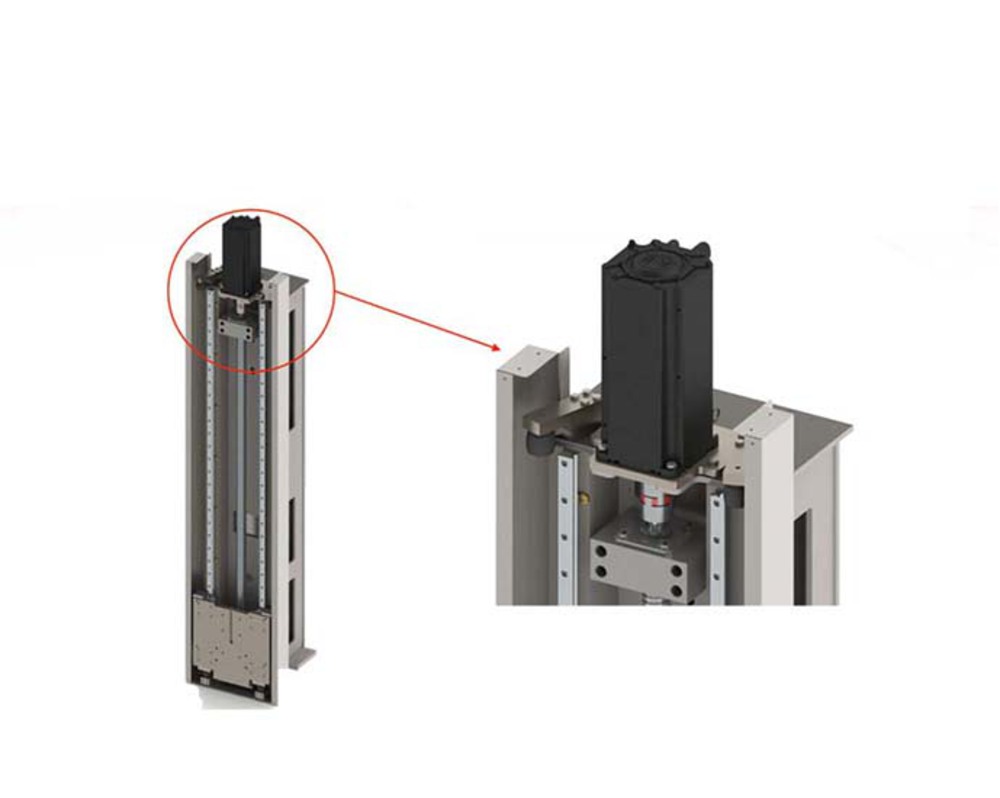

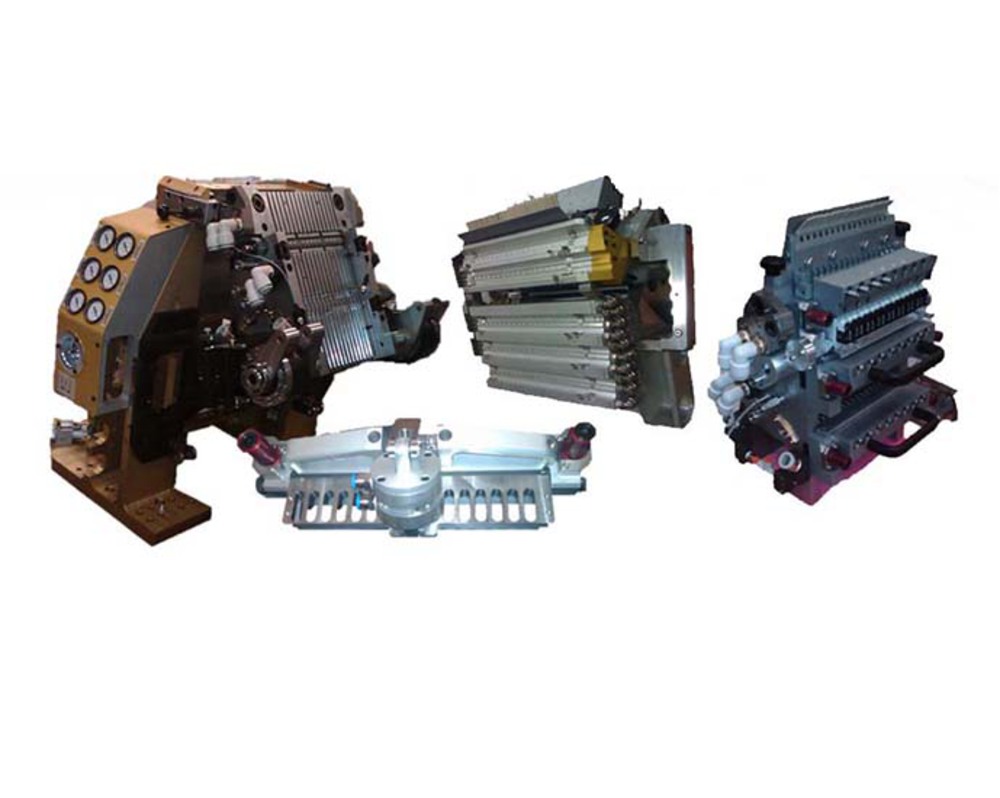

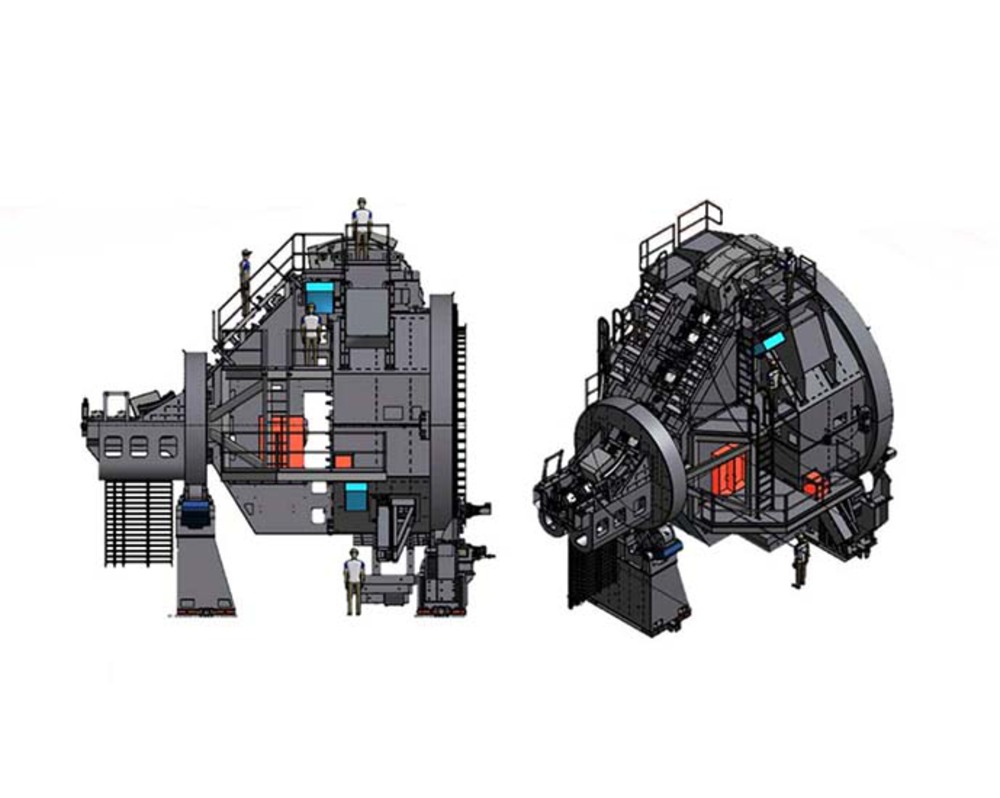

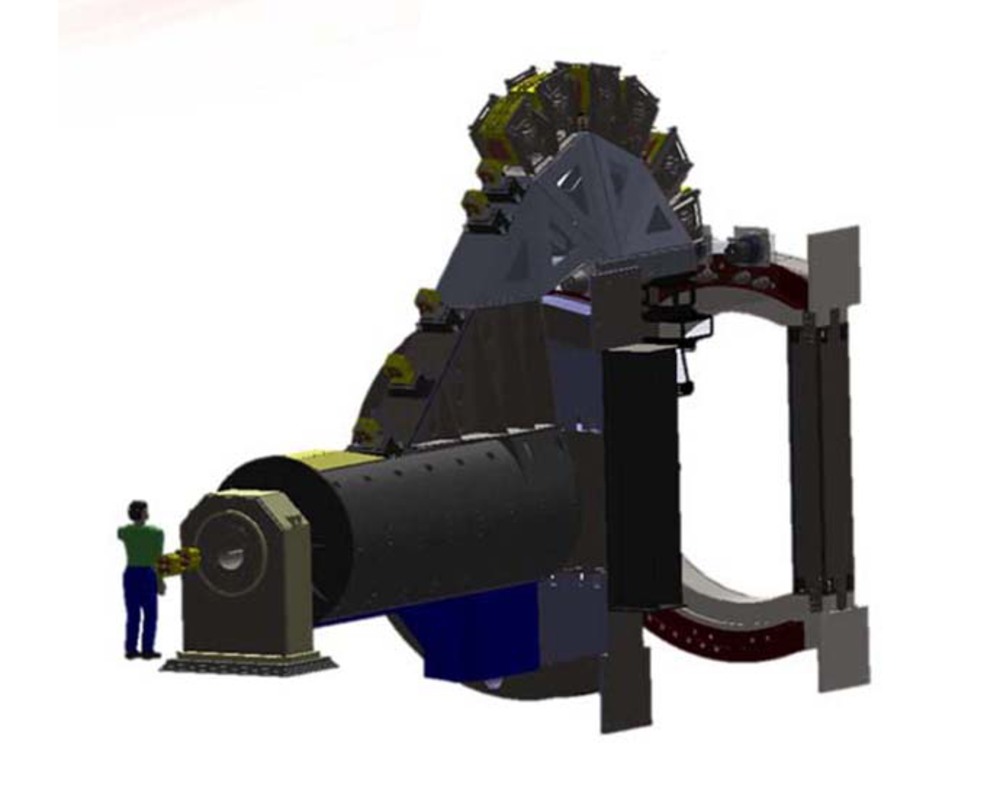

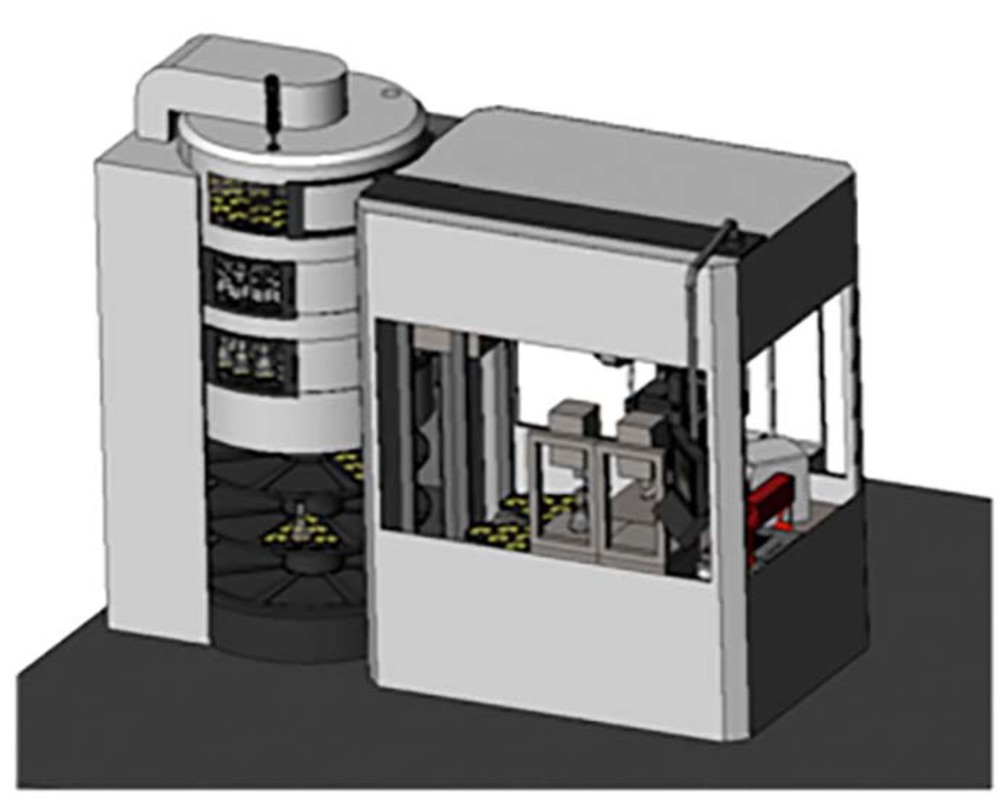

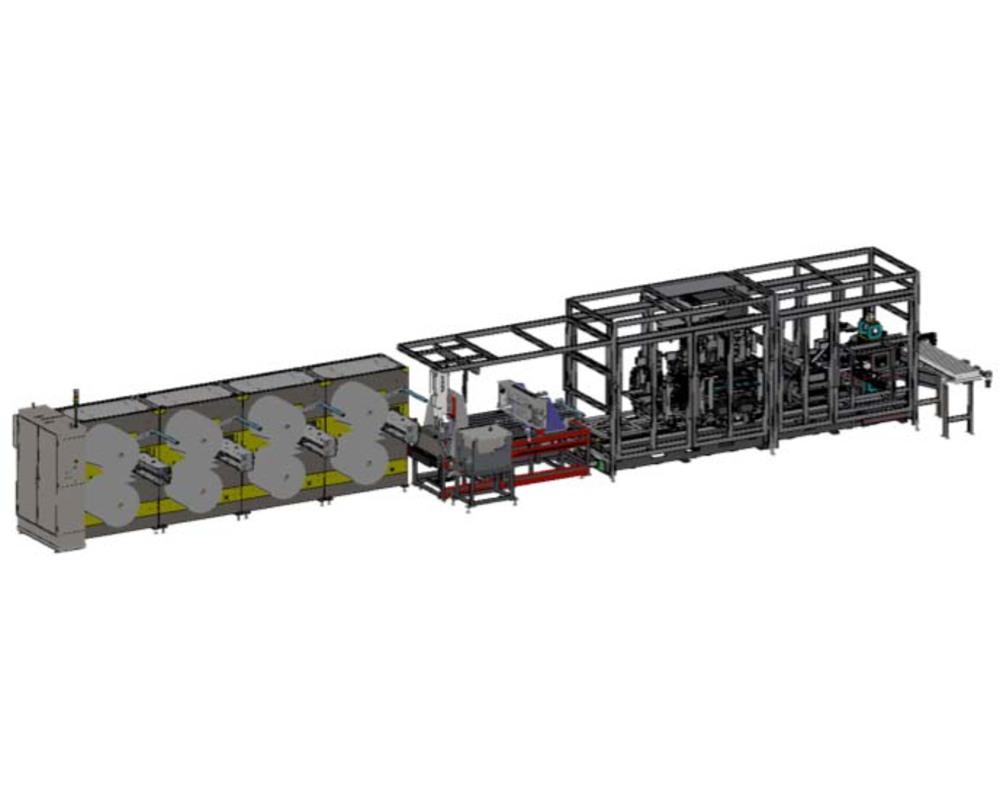

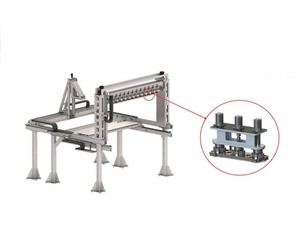

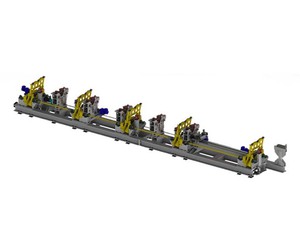

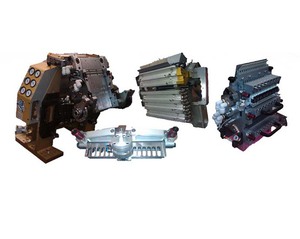

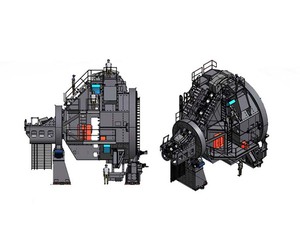

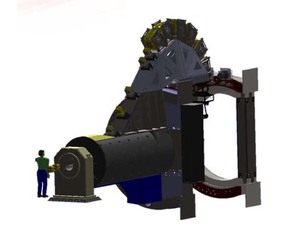

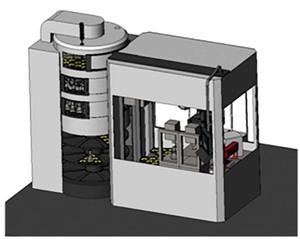

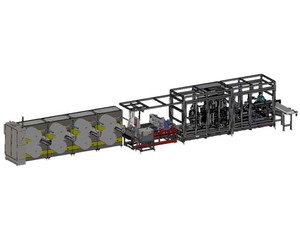

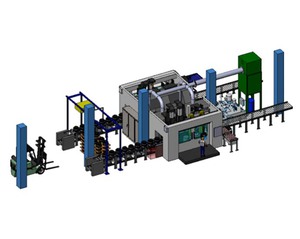

DESIGN/BUILD SHOWCASE

DESIGN-BUILD CAPABILITIES

Industrial Series

- Machine tools

- Sawing machines

- Welding & fabrication machines

- Grinding & polishing machines

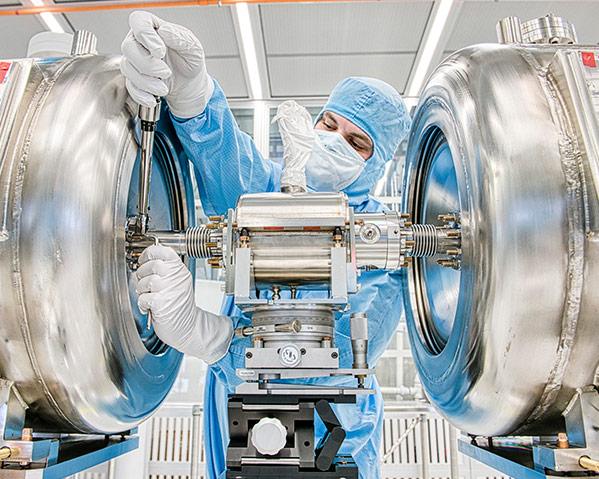

- Precision positioning systems

- Robotic systems

Discovery Series

- Indigo

- Harbor

- Sierra

- Lab robotics

- Lab automation

- Precision positioning slides

Custom Series

- Automation systems

- Processing equipment

- Converting equipment

- Electrical systems

THE AMD&E CHECKLIST GUIDES YOU THROUGH THE BUILDING PROCESS

The Design Build Process

The AMD&E checklist guides us through the process of understanding your challenges and specific needs in order create an engineered solution and build that will meet the objectives of your operating environment with a solution that will perform reliably for years to come. Then we support it with technical assistance, training, field service and parts to ensure maximum uptime and productivity.

Learn Your Challenges & Needs

Learn your current process and ask the right questions to identify the correct problem.

Engineered Solution

Our cross-functional team brainstorms the problem using our multi-industry experience to develop an engineered solution.

Helical Design Approach

Apply a helical review to ensure the solution meets your functional requirements and is optimized for manufacturing, assembly, maintenance, and life cycle costs.

Build

Our precision manufacturing and build process follows our proven path to ensure your system has a long productive service life.

Factory Acceptance Test

All systems undergo our rigorous Factory Acceptance Testing (FAT) at our facility before shipping. Results are documented to establish a performance baseline for your machine.

Deliver

We handle all logistics and follow DOT standards to professionally packaged using ISPM-15. All connections labeled and protected. Packages shipped in numeric order to facilitate future reassembly.

Install

& SAT

We can provide installation, initial start up, Site Acceptance Test (SAT), and team training to ensure performance at factory standards, system operation, and proper maintenance.

360°

Support

Our long term support includes preventative maintenance, spare parts, field service, future upgrades and add-ons to ensure your system remains state of the art and in top condition.

Markets We Serve

Space, Aerospace, Defense, Military

Energy

Clean Water, Food & Beverage

Biotech, Life Sciences, Agri Science

Healthcare Equipment

Agriculture, Off-Highway & Automotive Machinery

General Manufacturing & Industry

Precision Machinery Industry